Electrical Solutions for the Injection Molding Industry

October 27, 2025

The Injection Molding Industry Project showcases KRIPAL’s commitment to providing smart, durable, and safe electrical connection solutions for high-demand industrial environments.

Injection molding machines are the backbone of modern manufacturing, producing plastic parts for everything from automobiles and electronics to medical equipment and home appliances.

These machines run under high temperature and pressure, requiring a stable and efficient power system to maintain continuous operation and ensure product consistency.

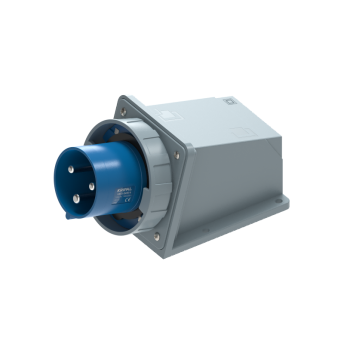

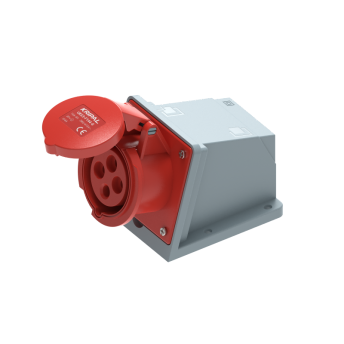

KRIPAL’s electrical components, including industrial sockets, plugs, and interlocked outlets, play a key role in keeping these systems running safely and efficiently in factories across China and worldwide.

Project Overview

The project site is a large-scale injection molding equipment production workshop, equipped with multiple automated machines running simultaneously. Each unit consumes a considerable amount of electricity, with different sections requiring separate power inputs for heaters, motors, cooling systems, and control panels.

KRIPAL was selected to provide industrial-grade power connection solutions that could meet the demanding needs of continuous manufacturing while ensuring high levels of electrical safety and maintenance convenience.

The key goals were clear:

- Guarantee a stable power supply to each injection machine

- Ensure safe connections that can handle high current and temperature

- Make maintenance quick and easy, minimising downtime

- Deliver a modular design adaptable to future upgrades or reconfiguration

KRIPAL’s Technical Solution

To meet these requirements, KRIPAL supplied a full range of IP67 industrial sockets and plugs, known for their waterproof, dustproof, and impact-resistant design.

The sockets are built to comply with IEC 60309 standards, ensuring compatibility and safety in all industrial settings.

Each injection molding unit was fitted with KRIPAL industrial outlets on the machine base, offering secure and easy access for electrical connections. The sockets’ red and gray casings are made from flame-retardant materials, providing extra protection against heat and accidental short circuits.

The system also integrates mechanical interlocks, which prevent the plug from being removed while the circuit is live — a critical feature for operator safety.

This design helps prevent electrical arcing and ensures long-term stability even with frequent plug-in and unplug operations.

Performance and Benefits

Once installed, the KRIPAL system demonstrated exceptional performance.

Each socket maintained a tight, vibration-resistant connection, even during continuous machine operation. The high mechanical strength of the socket housings meant that exposure to dust, oil mist, and factory humidity did not affect performance.

Maintenance technicians quickly noticed the benefits — connections could be easily inspected and serviced without disrupting production. The modular socket arrangement allowed teams to isolate specific lines for repair or testing while keeping the rest of the machines in operation.

The plant reported a significant reduction in electrical issues, such as overheating and contact failure, which previously caused costly downtime.

Thanks to KRIPAL’s industrial sockets, power distribution became more organized, safer, and easier to manage across the entire production floor.

Client Feedback

The client praised KRIPAL’s products for their durability, professional design, and user-friendly structure.

They highlighted that the KRIPAL solution not only improved equipment reliability but also enhanced workplace safety standards.

Machine operators appreciated how easy it was to identify the sockets by color and layout, while the maintenance team valued the quick installation and robust construction that stood up to daily heavy use.

The client also noted that KRIPAL’s team provided excellent technical support, offering guidance on installation layout, safety testing, and optimization of power circuits for maximum performance.

Why KRIPAL for Injection Molding Applications

Injection molding machines are complex systems that demand precision and continuous operation.

KRIPAL’s industrial connectors are designed to meet these challenges head-on, combining electrical safety, mechanical reliability, and long service life.

Whether it’s a single machine or a full-scale production line, KRIPAL solutions provide:

- High current capacity for motors and heaters

- Excellent resistance to vibration, dust, and oil

- Quick and safe maintenance access

- Compliance with CE, CCC, and IEC standards

- Long-term stability under continuous operation

By delivering products that improve efficiency, safety, and ease of use, KRIPAL continues to support the injection molding industry’s progress toward automation and smart manufacturing.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.