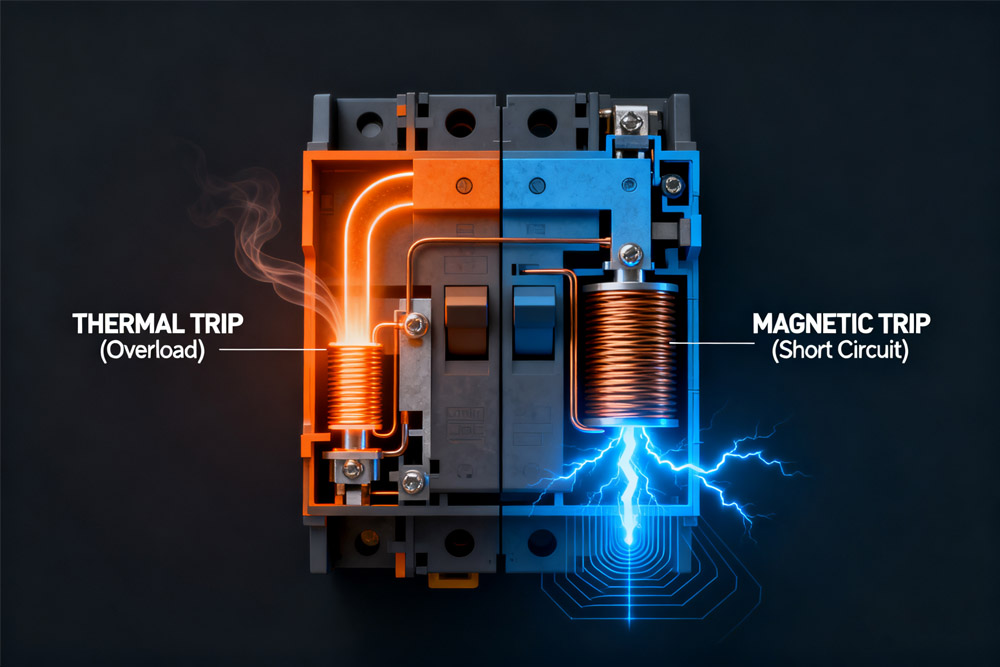

A thermal‑magnetic breaker combines two methods of detection. One method responds to slow build‑up currents that exceed rated capacity over time. The second reacts to rapid surges or short circuits that produce sudden high current spikes. The two together provide a balanced way to protect circuits under different stress conditions.

Inside the breaker, a bimetallic strip bends as it heats when the current exceeds a safe value for a period. The bending of that strip eventually triggers the mechanism that opens the circuit when overload persists. This handles situations where many devices draw power at once, or where a continuous load slightly above the rating creates gradual heating.

For sudden surges, the breaker uses a magnetic coil. A rapid increase in current generates a strong magnetic field. That field pulls a metal plunger or armature, which activates the trip mechanism swiftly. This fast response interrupts the current almost immediately when a short circuit or major fault occurs.

Because of this dual detection, the breaker protects against both slow overloads and sudden surges. That makes it suitable for applications ranging from residential wiring and small appliances to heavy‑load circuits and industrial equipment.

What Happens When the Breaker Trips

When overload or surge is detected, the breaker’s internal mechanism opens the contacts that carry current. Before contacts separate, an electrical arc may form between them because current tries to keep flowing. The breaker includes an arc‑extinguishing structure to handle that arc safely and quickly. Once the contacts fully separate, the current stops. The fault current or overload disappears.

After the issue is fixed, the breaker can be manually reset to restore normal operation. This reusability avoids the cost and downtime associated with single‑use fuses.

Where Thermal‑Magnetic Breakers Are Used

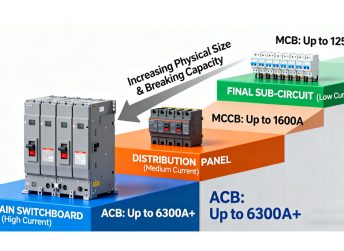

Thermal‑magnetic breakers find wide use because they offer flexible protection under varied conditions. In homes, they guard lighting circuits, outlet lines, and kitchen or household appliance circuits. In commercial buildings, they protect lighting and socket circuits, small machines or equipment. In small factories or workshops, breakers protect motors, control panels, feeders, and general equipment.

In larger installations, they can be used for sub‑panels or feeder lines. When the main supply requires more robust protection breakers with higher ratings or a different architecture may be selected.

What to Check When Using Thermal‑Magnetic Breakers

When you select a thermal‑magnetic breaker, match its current rating to the actual load demand. If load draws near or above rated current for extended periods, choose a breaker with a higher rating. If devices have high startup current, such as motors, choose a breaker whose magnetic trip threshold tolerates inrush current.