Selecting a circuit breaker that matches your circuit demands and installation conditions sets a foundation for safety and reliability. This guide outlines the main steps from load estimation to final breaker selection.

Estimate the Total Load Current

Begin by listing every device, fixture or equipment connected to the circuit. Include their rated power or expected current consumption. For alternating current circuits, convert power to current.

- In a single‑phase system, use current = power ÷ voltage.

- In a three‑phase system, use current = power ÷ (voltage × √3 × power factor).

If the circuit serves devices that run continuously over long periods, use the steady continuous current for sizing. If the circuit sees intermittent operation or equipment with startup surge current, like motors or compressors, include those peak or inrush demands in your calculations. That gives a realistic view of worst case conditions.

Add up individual load currents to find the total expected current draw. This value serves as baseline for breaker sizing.

Choose Breaker Rating with Margin

After determining total load current choose a breaker whose rated current exceeds this load by a margin. That margin helps avoid unwanted trips caused by normal fluctuations in load or temporary surges.

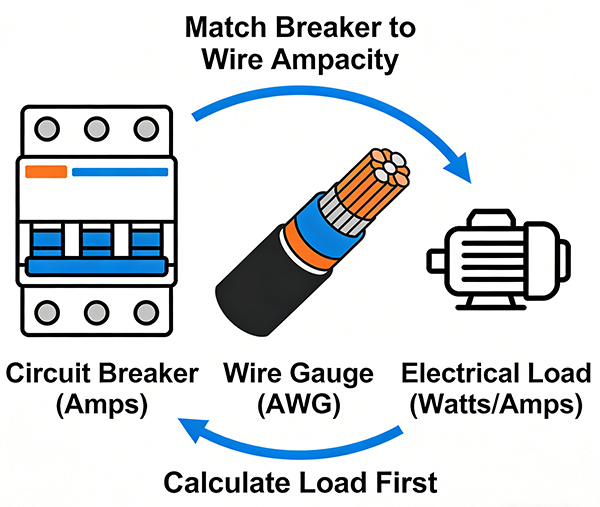

Once you have a candidate breaker rating, double‑check the wiring or conductor gauge of your circuit. The wire used must safely carry current equal to or above the breaker rating. If conductor ampacity falls short, risks such as overheating or insulation damage appear even if breaker is correct.

Always pick a standard breaker rating rather than a custom one. Standard ratings simplify sourcing of replacement breakers and help ensure compatibility with panels and protection systems.

Confirm Interrupting Capacity and System Compatibility

Breaker selection requires more than matching current rating. Verify that the breaker’s interrupting or breaking capacity handles the maximum possible fault current in the installation. Without adequate breaking capacity, even a correctly rated breaker may fail under fault conditions.

Ensure the breaker matches system voltage and phase configuration. A breaker rated for single‑phase will not work properly in a three‑phase supply. The voltage rating must equal or exceed system voltage under all operating conditions.

Account for Load Types and Startup Conditions

Circuits powering motors, compressors, heavy machinery or equipment with inrush current need special attention. For these circuits a breaker must tolerate brief high currents without tripping unnecessarily. In practice this may mean selecting a breaker with appropriate time‑current characteristic or adjustable trip behavior.

For purely resistive loads, like lighting, heating or small appliances, standard breaker ratings generally suffice once wiring and load current are verified.

Match Wiring, Ambient Conditions and Derating Factors

Cable or wire gauge must be matched to breaker rating. Check ampacity tables for conductor size under expected temperature, grouping of conductors, conduit fill and environmental conditions. Derating may reduce allowable current capacity of wiring, thus affecting the maximum safe breaker rating for that circuit.

Avoid using a breaker whose rating exceeds conductor capabilities. That mismatch defeats the protection purpose and poses hazard even under normal load.

Review All Conditions Before Finalizing

Before final selection, gather all relevant data.

- total expected load current

- breaker rating, conductor ampacity

- interrupting capacity

- voltage and phase

- load type and stability

- startup or surge demands

- environmental

- installation conditions.

If any parameter does not match or leaves little safety margin, adjust breaker rating, conductor size or circuit design accordingly. Always think ahead. If load may increase in future, plan for some headroom while staying within safe wiring limits.

Final Thoughts

Selecting correct circuit breaker size involves many conditions. Taking time to analyze each factor before installation reduces the risk of overload, false trips or unsafe conditions.

If you want reliable, quality‑grade breakers and help matching them to your installation needs, contact Kripal for a professional quote today.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.