When we talk about breakers we often see abbreviations such as MCB, MCCB and ACB. These labels refer to three types of circuit breakers that serve different roles in power distribution. Understanding what each stands for and how they differ helps you pick the right one for a given application.

MCB: Miniature Circuit Breaker

MCB means Miniature Circuit Breaker. This type is compact and built for lower‑current, low‑voltage circuits. It is widely used for household wiring or light‑duty circuits. Typical applications include protecting lighting circuits, wall sockets, small appliances, and other circuits that draw moderate current.

An MCB offers over‑current and short‑circuit protection for circuits usually below about 100 A or the lower end of low‑voltage distribution. It responds to overloads or faults by interrupting current flow, and after the issue is resolved, you can simply reset it. Its compact form and straightforward design make installation and maintenance simple and convenient.

Since MCBs suit circuits with stable or predictable loads, they are common in residential wiring, small commercial buildings, or office lighting and outlet circuits. Their smaller size helps fit into compact distribution boxes and panels.

MCCB: Moulded Case Circuit Breaker

MCCB refers to Moulded Case Circuit Breaker. Its housing is moulded, often plastic or resin, and its internal components are engineered to handle higher current loads than MCBs. MCCBs cover a wider current range, sometimes from tens of amps up to several hundreds or even over a thousand amps, depending on the model.

MCCBs also offer more flexible performance. Many models support adjustable trip settings. That gives them adaptability to different kinds of loads from simple resistive loads to motors, pumps or mixed loads. This adjustable trip feature helps the breaker distinguish between harmless short surges and harmful overloads.

Because of their higher capacity and flexibility, MCCBs are suitable for sub‑distribution panels, feeders, circuits supplying motors, HVAC systems, medium‑power equipment, or in light industrial settings. They strike balance between robustness and implementability.

ACB: Air Circuit Breaker

ACB stands for Air Circuit Breaker. This type is designed for larger installations and heavier load demands. ACBs support high current flows and high fault current capacity. They often serve as main incoming breakers in commercial buildings, factories or large electrical installations where overall power demand is large.

Air Circuit Breakers use air (or in some designs air under pressure) as the medium to extinguish arcs when contacts open. This makes them capable of handling high‑power interruptions safely.

ACBs often support high fault clearing capacity, high rated current, and work under more demanding conditions compared to MCBs or MCCBs.

Because of their capacity, ACBs usually occupy more space, require proper installation and maintenance, and are typically handled by trained personnel. They serve as central protection points for main supplies feeding entire buildings or large installations.

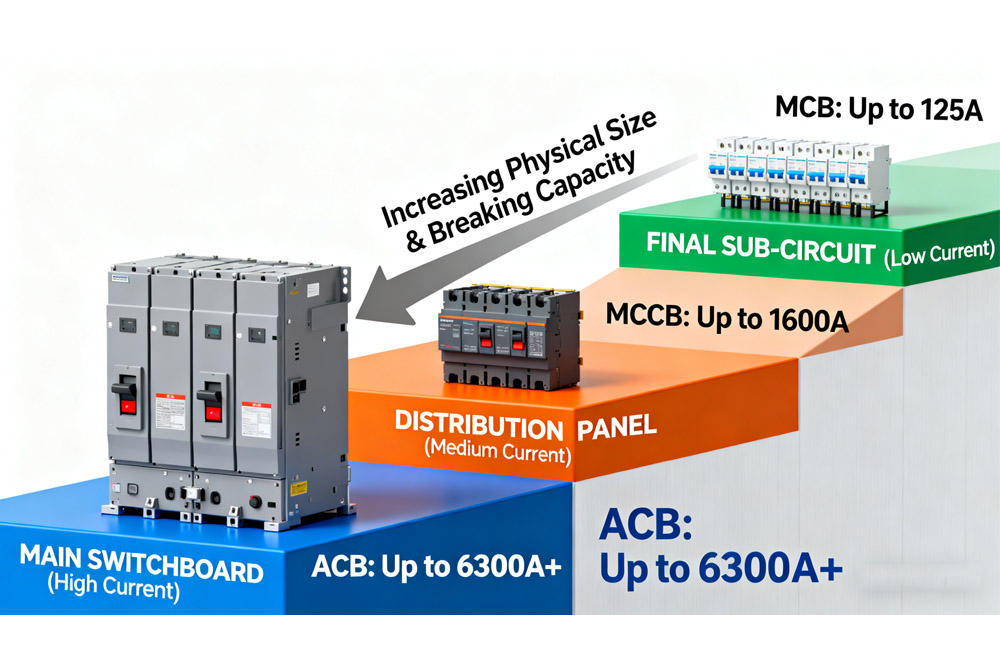

How the Three Fit into a Distribution System

A well‑designed electrical distribution system often uses all three types in a layered setup. The top layer uses an ACB at the main supply to guard against large faults or overloads from entering the system.

Downstream feeders or sub‑panels often employ MCCBs to manage moderate to heavy loads or mixed usage. At the final circuits, MCBs offer compact, cost‑effective protection suitable for stable, lower‑current demands.

This layered approach ensures each circuit uses a breaker with a capacity matched to its role. It avoids over‑engineering simple circuits and avoids under‑protecting heavy‑duty or high‑fault potential lines. The result is balanced performance, reliability and efficient use of resources.

Why Each Type Matters Depending on Load and Demand

- When the load is simple and predictable, an MCB fits well because of its simplicity, small size and cost effectiveness.

- When the load is heavier, or includes motors, variable demand, or mixed devices, an MCCB offers better flexibility and adequate capacity.

- When supply demands are great, or fault current potential is high, an ACB provides robust interruption capability and high‑current support.

Choosing the right type prevents issues such as frequent trips, wiring damage, false protection or under‑specification which might lead to unsafe conditions.

What to Check When Selecting Between MCB, MCCB and ACB

When selecting a breaker, you should examine several factors beyond just the type.

These include:

- The current rating of the circuit

- Expected load (steady or variable)

- Whether loads include motors or devices with inrush current, phase configuration (single or three phase),

- Whether the circuit supplies a branch, feeder or main distribution.

Also consider interrupting capacity, especially where fault currents may be high. Installation environment factors include ambient temperature, ventilation, physical space, maintenance access, and whether professional installation is required.

For circuits with mixed or heavy loads, adjustable‑trip MCCBs or properly rated ACBs provide more flexibility and stability than simple fixed‑trip MCBs. For stable, low‑current circuits, home lighting or outlets remain safe under MCB protection.

Summary

MCB, MCCB and ACB bring different strengths. MCB offers compact, simple protection for low‑current circuits. MCCB adds capacity and adjustable protection for varied loads and medium circuits.

ACB supports high currents and robust interruption for main supply and heavy power distribution. A layered combination of these breakers ensures each part of an electrical system uses appropriate protection matched to its load and role.

When you need reliable breaker options covering from small circuits to heavy‑duty power distribution, contact us to check solutions at Kripal Electric.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.