Key Takeaway

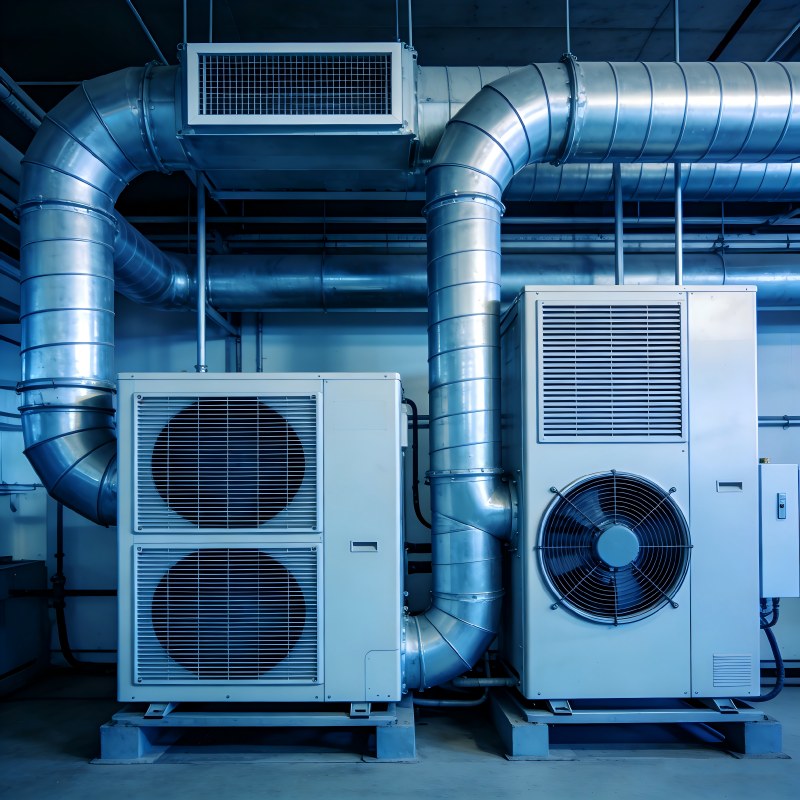

HVAC systems are widely used to manage indoor temperature, airflow, and air quality across residential, commercial, and industrial buildings. From private homes and office buildings to hospitals, factories, and data centers, HVAC systems support consistent environmental control at different scales.

Understanding how HVAC systems are structured and how electrical components such as contactors are installed and applied helps system designers, contractors, and facility managers maintain stable operation and reduce long-term maintenance issues.

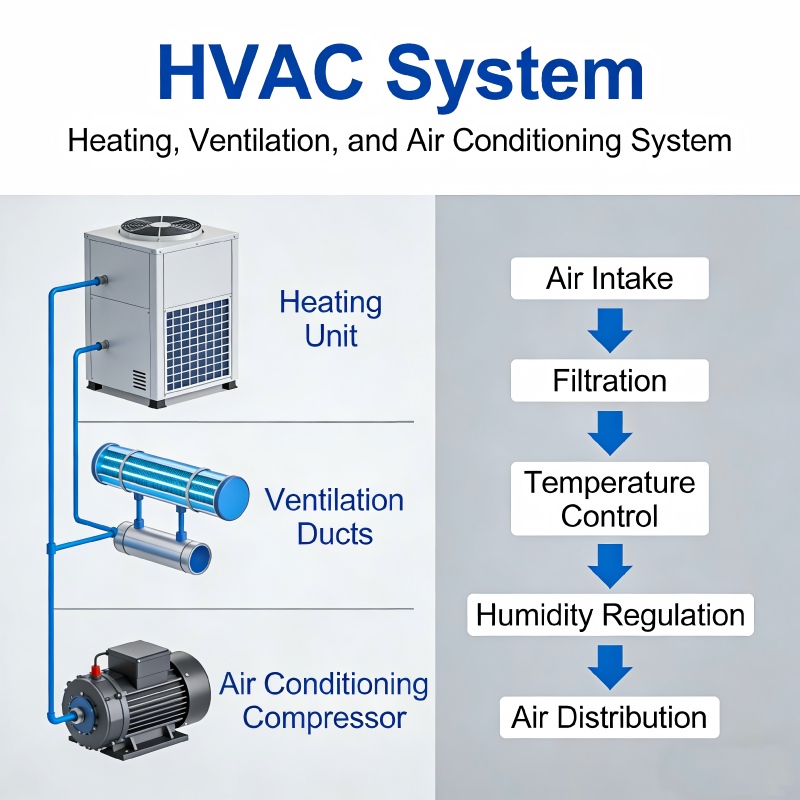

What Is an HVAC System?

HVAC stands for Heating, Ventilation, and Air Conditioning. An HVAC system combines these three functions into a single coordinated solution designed to regulate indoor temperature and air circulation.

HVAC systems can be configured to serve individual rooms, multi-zone buildings, or large facilities. This adaptability allows their use in residential housing, commercial properties, industrial plants, medical environments, and data centers. By integrating heating, cooling, and ventilation, HVAC systems simplify system control and allow centralized operation and maintenance.

Main Components of an HVAC System

Heating Components

Heating functions maintain indoor temperature during cold conditions. Common components include blower motors that move heated air through duct systems, electric heating elements used in furnaces or air handlers, and thermostats that send control signals based on preset temperature values.

Ventilation Components

Ventilation supports air exchange and indoor air quality. Exhaust fans remove moisture and odors from areas such as bathrooms and kitchens, while duct fans assist airflow over long duct runs. Some modern HVAC systems include air filter sensors that notify users when filters require replacement.

Air Conditioning Components

Cooling functions rely on compressors to circulate refrigerant and remove heat from indoor spaces. Condenser fans dissipate heat outdoors, and evaporator fans distribute cooled air inside the building. Together, these components support temperature control under varying load conditions.

Electrical Maintenance Considerations for HVAC Systems

HVAC equipment operates for long periods and places continuous demand on electrical infrastructure. Practical electrical considerations include:

- Supplying heating and cooling equipment through dedicated circuits

- Investigating frequent circuit breaker trips rather than simply resetting them

- Replacing thermostat batteries to prevent control interruptions

- Verifying electrical panel capacity before system installation

- Selecting cables rated for temperature and current based on NEC Table 310.16 or local standards

These steps help avoid overheating, nuisance trips, and premature component wear.

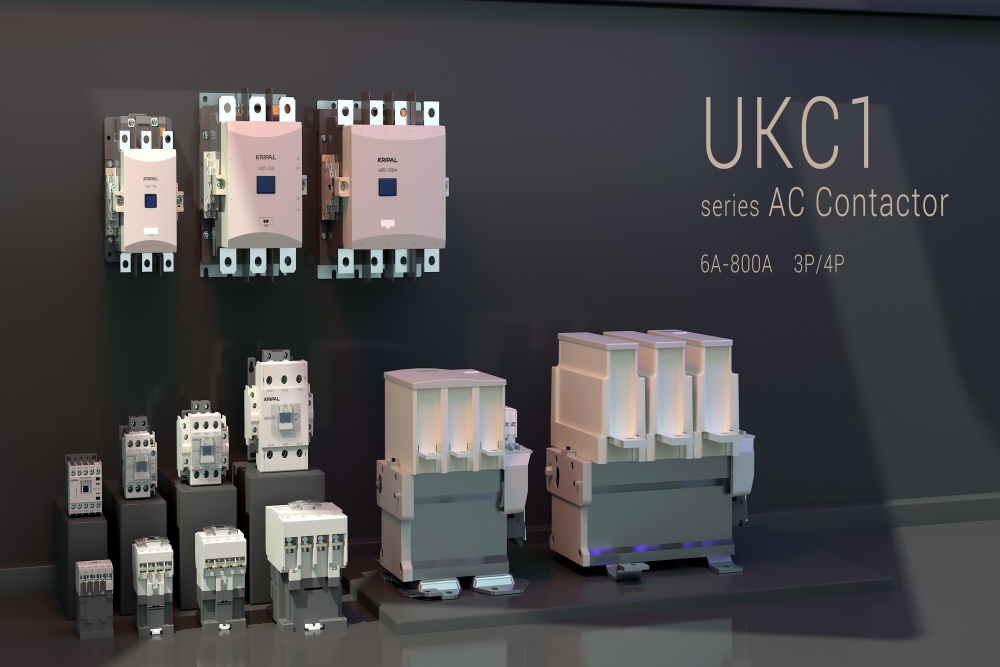

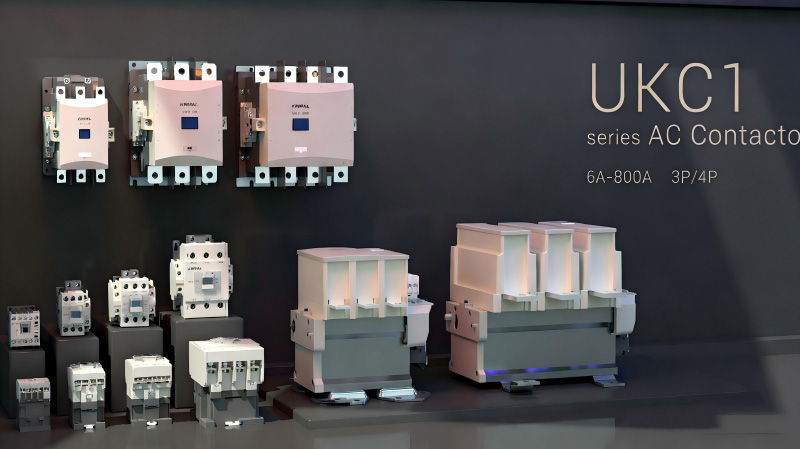

How Contactors Are Used in HVAC Systems

Contactors are commonly used to control high-current loads in HVAC systems. Typical applications include:

- Supply and exhaust fans

- Water circulation pumps

- Compressors

- Fan coil units and air handling units

They allow automatic or remote control through thermostats, PLCs, or building management systems. Correct contactor selection supports stable switching behavior and predictable motor operation.

AC-3 vs AC-1 Contactors in HVAC Applications

HVAC loads are not all the same, and contactor category selection matters.

| Contactor Category | Typical Load Type | HVAC Use Case |

| AC-1 | Non-inductive or slightly inductive loads | Resistive heating elements, control circuits |

| AC-3 | Motor loads with high starting current | Fans, pumps, compressors |

Why AC-3 Is Common in HVAC Systems

Most HVAC motors are squirrel-cage induction motors. When these motors start, the inrush current can reach five to seven times the rated current. AC-3 contactors are designed to handle this repeated electrical stress during normal start and stop operation.

AC-1 contactors, by contrast, are intended for resistive loads and are not suitable for frequent motor starting. Using AC-1 contactors on motor loads can lead to contact wear, overheating, and reduced service life.

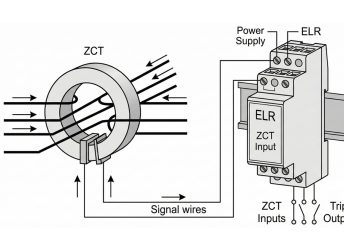

For three-phase HVAC equipment, contactors must disconnect all phases simultaneously and operate together with thermal overload relays or electronic motor protection devices.

Installation Guidelines for HVAC Contactors

Proper installation helps maintain stable operation and reduces maintenance issues.

Recommended installation practices

- Installing contactors in dry, ventilated locations away from condensation and corrosive gases

- Using enclosures that meet required IP protection levels, especially outdoors

- Selecting DIN rail mounting for ease of maintenance in standard control panels

- Using screw mounting for larger contactors, typically 65 A and above, to improve mechanical stability

- Maintaining sufficient spacing for heat dissipation

Typical Spacing Guidelines

- Clearance around contactor: ≥ 50 mm

- Spacing between multiple contactors: ≥ 30 mm

- Larger current devices may require additional spacing or forced ventilation

Poor thermal management can increase operating temperature and shorten component lifespan.

Electrical Control Reliability in HVAC Operation

HVAC systems operate under varying loads and frequent switching cycles. Electrical control components experience thermal and mechanical stress over time. Applying correctly rated contactors and following standard installation practices supports consistent operation and reduces unexpected downtime.

In larger facilities, stable HVAC operation affects comfort levels, process consistency, and energy use, making electrical control design a practical consideration rather than an afterthought.

Conclusion

HVAC systems integrate heating, ventilation, and air conditioning to support indoor comfort across a wide range of building types. Their performance depends on both mechanical equipment and electrical control components working together.

Contactors are widely used to control motors and high-current loads in HVAC systems. Selecting AC contactors for motor applications, installing them correctly, and following electrical standards helps maintain safe and stable operation over long service periods.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.