Circuit breakers are fundamental components in electrical systems. They protect circuits against overloads, short circuits, and other fault conditions. But to keep them effective and safe, correct usage and handling are essential. Improper installation or maintenance may undermine protection, cause hazards or even lead to injury.

Basic Safety Practices Before Working on Panels

When you plan to inspect or maintain a breaker panel first ensure the power is completely isolated. Use a lockout‑tagout (LOTO) procedure to prevent accidental re‑energization during work. Such a procedure greatly reduces the risk of electric shock or arc flash when handling breakers.

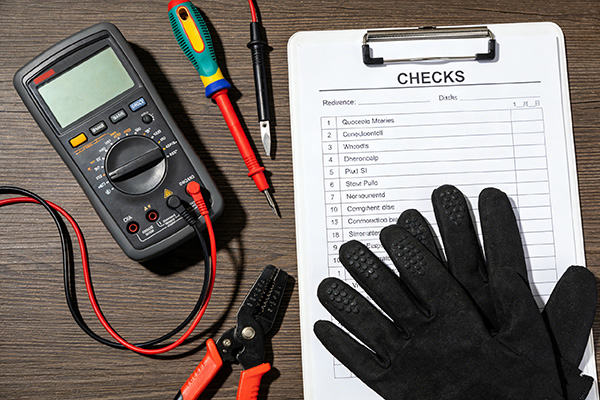

Wear suitable personal protective equipment before working on any live or possibly live panel. Insulated gloves, safety glasses, and flame‑resistant clothing help protect against shocks, sparks or arcs. Use tools with insulated handles only. Non‑insulated tools can conduct electricity and increase risk of injury.

When installing or removing a breaker, ensure all connections are tight and properly secured. Loose connections can lead to overheating, arcing or a fire hazard. After work is done, check that all terminals are properly tightened, covers are in place and no foreign objects remain inside the panel before restoring power.

Common Mistakes and Hazards to Avoid

Working on Live Circuits Without Proper Isolation

One frequent error is attempting to inspect or service a breaker panel without fully isolating power. If the panel remains energized, direct contact with live parts or accidental reconnection may lead to electric shock or arc flash. For safe maintenance it is advisable to perform a lockout‑tagout (LOTO) procedure to make sure the circuit cannot be re‑energized unexpectedly while work is ongoing.

Loose Wiring or Poor Connections

Wiring problems such as loose terminal screws, poor contact, or mismatched wire gauge can cause serious hazards. Poor connections may generate heat when current flows, leading to overheating, insulation damage or arcing. Over time this may degrade wiring integrity, trigger nuisance trips or even result in fire.

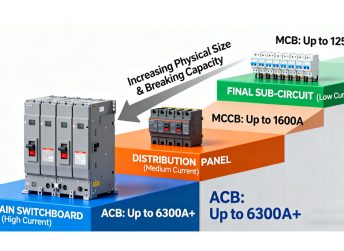

Installing the Wrong Breaker Type or Rating

Choosing a breaker with incorrect rating or type for the circuit is a mistake that undermines protection. A breaker with too low a current or interrupting capacity may not clear a fault safely. A breaker not rated for the system’s voltage or fault level may fail to interrupt fault current properly, exposing wiring and equipment to damage or fire hazard. Wrong selection often leads to recurring failures or unsafe operation.

Ignoring Environmental Conditions Around the Panel

Panels and breakers operate under environmental stress such as moisture, dust, heat, or corrosive atmospheres. Installing a breaker in a damp or dusty environment without protective enclosure increases risk. Insulation degradation or ingress of conductive dust may lead to leakage currents, ground faults or premature aging. Regular inspection and proper enclosure help prevent these environmental hazards.

Repeated Resetting After Frequent Trips Without Investigating Root Cause

When a breaker trips repeatedly and is simply reset without identifying the underlying cause, hidden faults may accumulate. This might mask wiring degradation, intermittent short circuits or overloaded wiring. Ignoring repeated trips can lead to serious safety hazards over time such as overheating, arcing or fire.

Routine Inspection and Maintenance Checklist

Here are key items to check periodically to ensure breaker panels remain safe and reliable:

- Inspect all wiring and connections for signs of discolouration, melting, overheating or burn marks

- Verify that breaker handles, labels and panel covers are intact and clearly marked

- Test ground‑fault and arc‑fault devices (if installed) according to their test procedures

- Confirm that the panel environment remains dry, clean and free of dust or conductive debris

- Ensure that any changes in load or addition of new equipment are reviewed so breaker ratings and wiring remain appropriate

Regular maintenance lets issues appear before they escalate into faults or fire risk. It also supports long service life of breakers and wiring systems.

Safe Use During Operation

When switching breakers or restoring power always stand to the side rather than directly in front. Arcing at the contacts may cause flash, sparks or hot gas. Keeping distance reduces personal risk. Also be mindful: sudden load changes or startup surges, for example when motors or heavy equipment start, may generate high current demand; make sure breakers and wiring are rated accordingly before engaging heavy loads.

If a breaker trips repeatedly, do not keep resetting it without investigation. Continuous trips signal an underlying problem — overload, ground fault, wiring issue or a defective breaker. Resetting repeatedly can stress the breaker mechanism or hide a hazard. Instead lock out the circuit and inspect loads and wiring before re‑energizing.

When to Call a Qualified Professional

Electrical systems can hide hazards that are not obvious to untrained eyes. If you observe repeated breaker trips, heating, burn marks, corrosion, loose wires or any abnormal behavior, engage a trained and qualified electrician. Only trained professionals with proper tools and protective equipment should handle complex wiring, breaker replacement or fault tracing.

DIY repairs or ignoring warning signs often lead to shock, fire or long‑term damage. Safety and compliance with codes depend on professional workmanship.

Safe use and handling of circuit breakers combines sound practices: isolate power before work, use suitable protective gear and tools, inspect wiring and panels regularly, avoid overloading or misuse, and treat breaker trips seriously rather than as irritations. Combining care, inspection and respectful handling maintains protection of circuits, equipment and people.

If you need reliable circuit breaker products or professional‑grade protection solutions for your electrical system, contact Kripal and ask for a quote.