When selecting a circuit breaker for any power system, the labels on its datasheet matter a lot. Among the most significant ratings are Icu and Ics. These define how much fault current a breaker can interrupt and whether it can still be used afterward. Picking a breaker with correct breaking capacity for your fault current scenario is a foundation for safety and reliability.

What Is Breaking Capacity

Breaking capacity, also called interrupting rating, indicates the maximum fault current a breaker can safely interrupt. When a short circuit or fault occurs the current may spike far above normal operating current. If the breaker cannot interrupt that current, it risks damage or failure.

Breaking capacity is always specified for a particular voltage and expressed in kiloamperes (kA). A breaker must have a breaking capacity rating equal to or greater than the maximum possible fault current at its installation point.

Within breaking capacity ratings, Icu and Ics serve different roles. Understanding both helps you match breaker performance to realâworld demands.

Definition of ICU

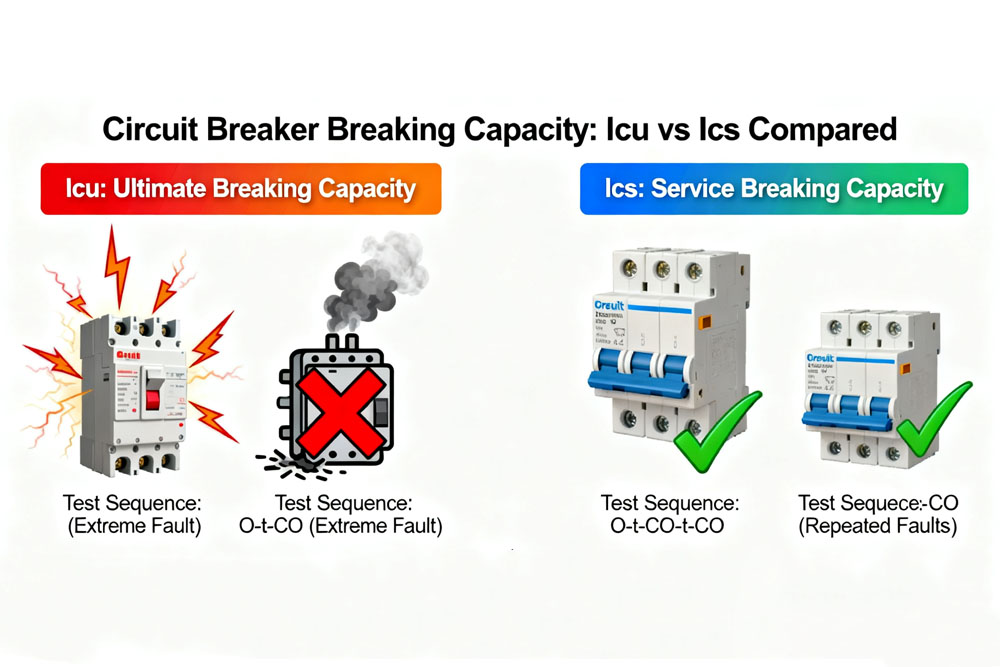

Icu stands for Ultimate Breaking Capacity. This rating shows the highest shortâcircuit current the breaker can interrupt one time under standard test conditions without causing catastrophic failure. After interrupting a fault at Icu level the breaker may no longer remain suitable for normal operation. As internal components, contacts, arc chambers or insulation, may suffer damage from the arc.

In practice Icu represents a âlastâresortâ scenario. The breaker is expected to clear an extreme fault that exceeds normal operating range. After such an event many standards recommend replacing the breaker to avoid hidden damage or degraded performance.

Definition of ICS

Ics stands for Service Breaking Capacity, sometimes called Rated Service ShortâCircuit Breaking Capacity. This rating defines the fault current level that the breaker can interrupt repeatedly while still remaining functional and safe for further use. After interrupting a fault at Ics level the breaker should retain its rated performance for normal operation.

Manufacturers often set Ics as a percentage of Icu. Common ratios include 50%, 60%, or even 100%. A breaker with Ics equal to 100% of Icu offers stronger resilience under fault conditions because it claims full recoverability even after high fault interruption.

Icu vs Ics: When Each Rating Matters

| Use Case | What Matters | Preferred Rating |

| Worst case short circuit, rare fault | Must interrupt maximum possible fault current even once | High Icu value matching or exceeding system prospective fault current |

| Normal operation under fault conditions with possible repeated faults | Breaker must remain functional after fault clearance | Ics rating high, ideally equal to Icu |

| Distribution panels or systems with frequent switching or potential faults | Flexibility and reliability for repeated operations | High Ics, good thermal and mechanical endurance |

| Critical systems where maintenance rapid reset is required | Minimize downtime and maintain safety after fault | Select breakers with strong Ics and tested endurance |

This comparison shows that Icu ensures survival in extreme fault scenarios. Ics ensures resilience and longer service life under repeated fault conditions. Choosing a breaker solely for Icu without regard to Ics may lead to forced replacement or unsafe operation after a fault.

What Happens if Fault Current Exceeds Icu

If the prospective shortâcircuit current in your system exceeds the breakerâs Icu rating the result may be severe. The breaker might fail to interrupt the fault, or it might succeed but suffer internal damage. Arcing contacts could weld, insulation could degrade and the arcâextinguishing system might be compromised. That creates serious risk for fire, equipment damage or further malfunction.

Regulations and design standards require that the breakerâs breaking capacity never be lower than the maximum expected fault current at the installation point. That means before specifying a breaker you should perform a shortâcircuit current calculation or measurement in your system.

Why Ics = Icu Breakers Offer Advantage for Installations

Breakers whose Ics equals Icu promise that after clearing a fault they retain full interrupting capacity. This reduces the need for immediate replacement. In industrial, commercial or highâavailability systems this reduces downtime, lowers maintenance cost and improves safety.

Such breakers support repeated fault interruption without degradation of contacts or arcâchambers. For installations with fluctuating loads, switching events, or possible grounding faults, having a robust breaker rated for repeated service increases system resilience.

Guidelines for Selecting Breaker Based on Fault Current and Load Conditions

- Estimate the prospective short circuit current at the installation point. This is the highest fault current that may appear under worst case conditions. Select a breaker whose Icu rating is equal to or higher than that value.

- If the system may face more than one fault during its service life, choose a breaker with a high Ics rating. For projects that care about reduced downtime and lower maintenance cost, prefer a breaker with Ics equal to Icu.

- Check mechanical endurance and thermal endurance values. Breakers with higher endurance can operate and trip many times without performance loss. This is especially useful when you plan to reset the breaker after a fault rather than replace it.

- Confirm that the voltage rating, current rating, number of poles and environmental ratings all match the real installation conditions. Even with suitable Icu and Ics values, a breaker that does not match system voltage or insulation requirements can still present a safety risk.

Summary

Understanding breaking capacity helps you match protection device capabilities to system demands. If you need circuit breakers with rated breaking capacity that meets your maximum fault current and expected load conditions, contact Kripal Electric for a quote. Kripal offers professionalâgrade MCCBs built for performance, safety and long service life.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.