Confusing a standard AC coil contactor with a DC coil model can lead to automation failures, excessive noise, or coil burnout. This guide compares their internal operating principles and performance limitations to help you select the correct component for manual or PLC-driven circuits.

How Coil Type Defines Contactor Performance

The control heart of any contactor is its electromagnetic coil. Whether the coil is powered by AC or DC directly determines the contactor’s behavior, its compatibility with other devices, and its suitability for automation.

The Standard AC Coil Contactor as a Traditional Workhorse

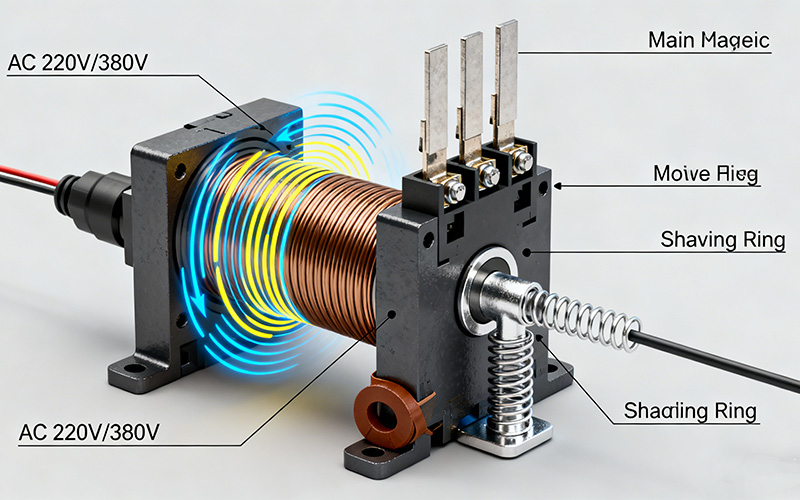

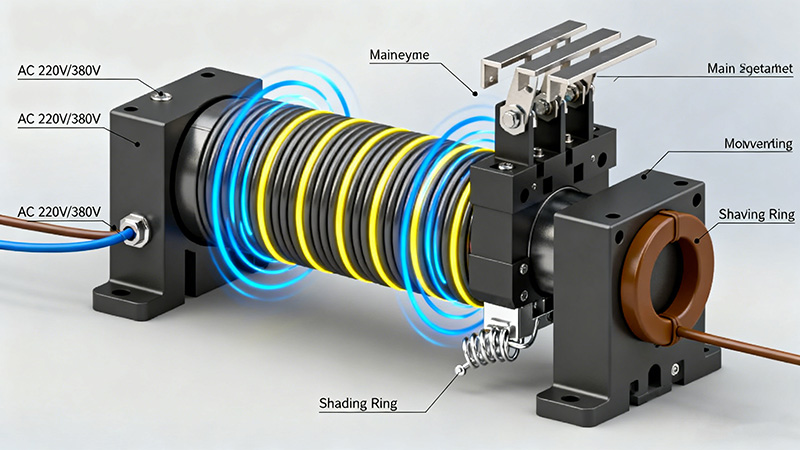

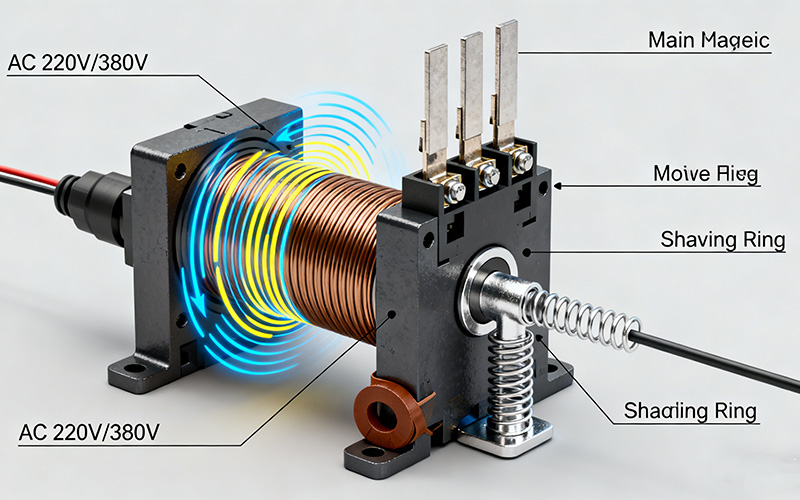

Working Principle

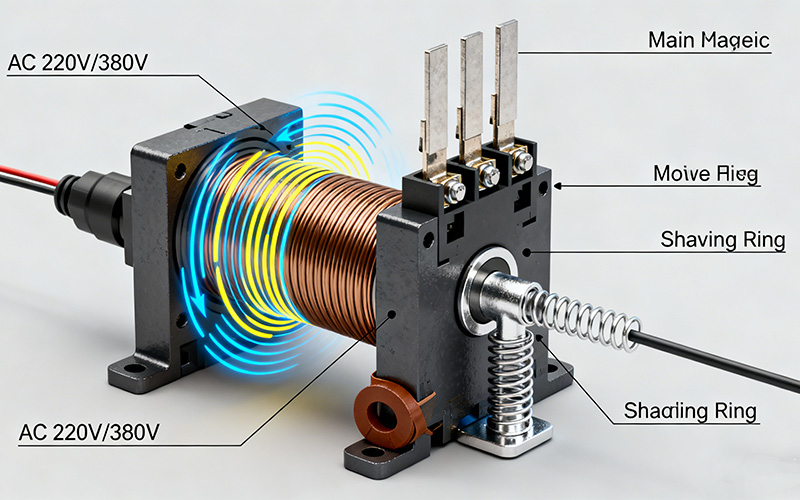

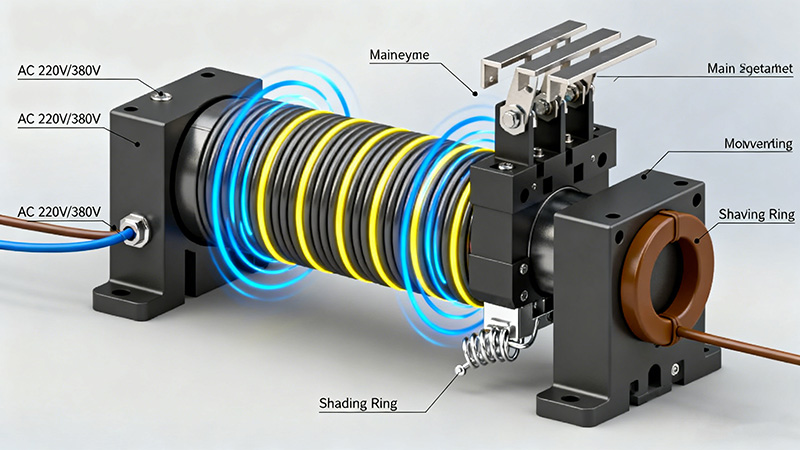

A standard AC contactor uses an AC-powered control coil, commonly rated for AC 220V or AC 380V.

When energized, the alternating current generates an alternating magnetic field. This attracts the moving core to the fixed core, closing the main contacts and energizing the load. When de-energized, a return spring separates the cores to disconnect the load.

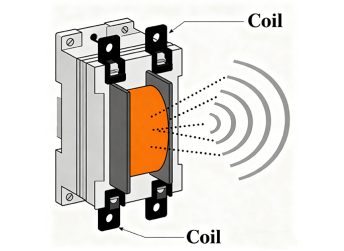

Because AC current crosses zero periodically, the magnetic field fluctuates. This can cause core vibration and audible humming. To reduce this effect, AC contactors are equipped with a shading ring, also known as a short-circuit ring.

Key Characteristics

- Simple wiringas the control voltage often matches the main circuit.

- No conversion requiredsince it connects directly to the AC supply.

- Higher thermal lossesdue to eddy currents and hysteresis.

- Noise increases over timeas shading rings age and wear out.

- Limited automation compatibilitymaking it less ideal for direct PLC control.

Why DC Coil-Controlled Contactors Are the Automation Choice

Working Principle

A DC coil-controlled AC contactor still switches an AC main circuit, but its control coil is powered by DC, most commonly 24V DC.

DC current produces a constant magnetic field. This results in stable core attraction with no magnetic fluctuation and no need for shading rings. The result is silent and smooth operation.

The biggest advantage lies in control signal compatibility. DC coils can be driven directly by PLCs, industrial controllers, and relay output modules, eliminating the need for AC/DC conversion.

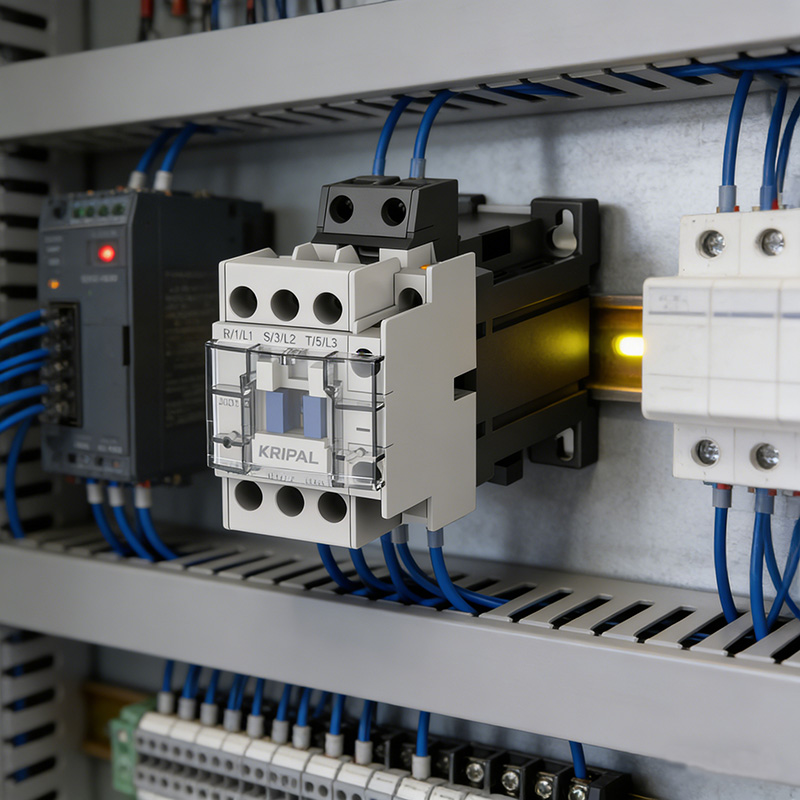

For example, KRIPAL’s UKD1 series DC coil-controlled contactors feature an optimized electromagnetic design. They offer strong attraction force and fast response, ensuring reliable operation even in electrically noisy industrial environments.

Key Characteristics

- Simple wiring as the control voltage often matches the main circuit.

- No conversion required since it connects directly to the AC supply.

- Higher thermal losses due to eddy currents and hysteresis.

- Noise increases over time as shading rings age and wear out.

- Limited automation compatibility making it less ideal for direct PLC control.

Get A Quote

Comparison for Choosing the Right Solution

| Comparison Aspect |

Standard AC Coil Contactors (KRIPAL UKC Series) |

DC Coil-Controlled Contactors (KRIPAL UKD1) |

| Control Signal |

Push buttons, AC relays |

PLCs, IPCs, DC relay modules |

| Typical Applications |

Manual control systems, standalone machines, cost-sensitive installs |

Industrial automation lines, solar PV, building automation |

| Key Advantages |

Low cost, simple wiring |

Silent, anti-interference, automation-ready |

| Limitations |

Noisy, not suitable for high-frequency PLC control |

Requires DC power supply |

System Integration and Coordination Schemes

Neither type of contactor works alone. Both must be integrated with protective and isolation devices to function safely.

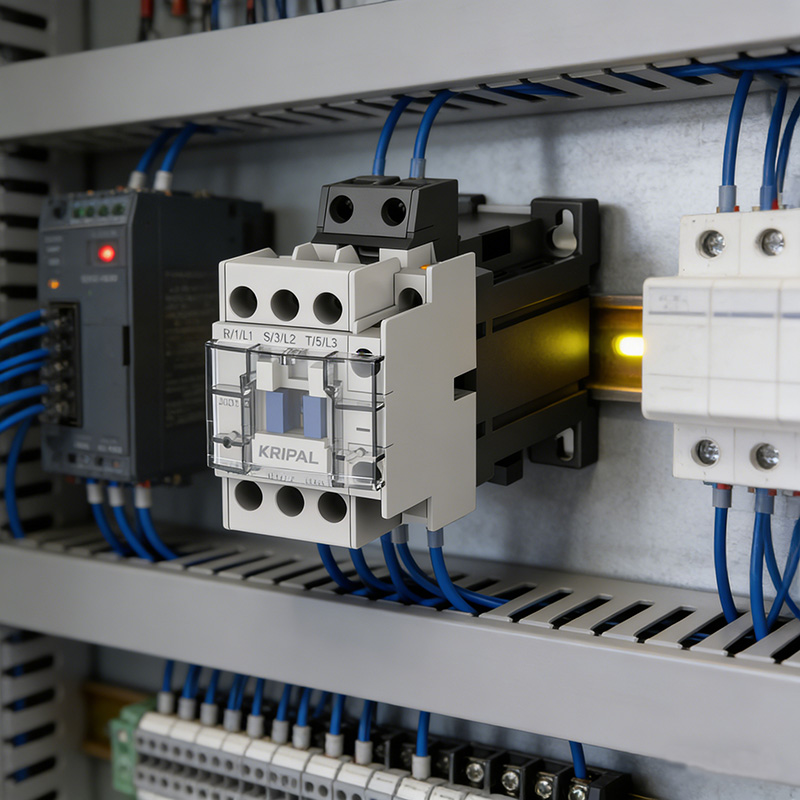

Standard AC Contactor Setup for Manual Control

This setup is typical for standalone machines like small air compressors.

Component Configuration

Isolator Switch + MCCB + AC Contactor + Thermal Overload Relay

Operating Logic

- The Isolator switch provides maintenance isolation.

- The MCCB protects against short circuits.

- The AC contactor receives manual AC control signals.

- The Thermal relay protects the motor from overload.

DC Coil-Controlled Contactor Setup for Automation

This setup is typical for automated production lines.

Component Configuration

Isolator Switch + MCCB + DC Coil AC Contactor + Thermal Relay + PLC

Operating Logic

- The Isolator switch ensures upstream safety.

- The MCCB protects the main circuit.

- The PLC outputs DC 24V control signals.

- The DC coil contactor executes precise switching commands.

- The Thermal relay provides overload protection and feedback to the PLC.

Important Design: Notes It is crucial to install a flyback diode across the DC coil to protect PLC outputs. Additionally, separate power and control wiring to avoid electromagnetic interference.

Frequently Asked Questions (FAQ)

Can standard AC and DC coil contactors drive the same load?

Yes. If the rated voltage and current of the main circuit match, both can control the same AC load. The difference lies only in the control circuit.

Can AC power be applied directly to a DC coil?

No. This will instantly damage the coil and may cause serious faults. DC coils must be powered strictly according to their rated voltage.

Are DC coil contactors worth the higher cost in automation systems?

Absolutely. They reduce wiring complexity, eliminate conversion modules, lower noise, extend service life, and reduce long-term maintenance costs.

How does the KRIPAL UKD1 series interface with PLCs?

The UKD1 series uses DC 24V coils, compatible with mainstream PLC brands such as Siemens, Mitsubishi, and Omron. Correct polarity and flyback protection ensure stable operation.

Summary on Matching the Control Requirement

To make the correct selection, you must look at your control source. Choose standard AC contactors if your system is simple, manually controlled, and cost-sensitive. Choose DC coil-controlled contactors if your system requires PLC control, frequent switching, silent operation, and high reliability.

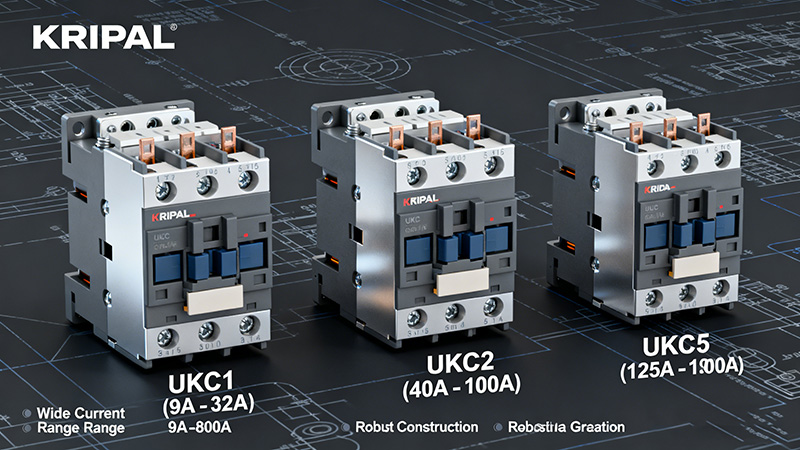

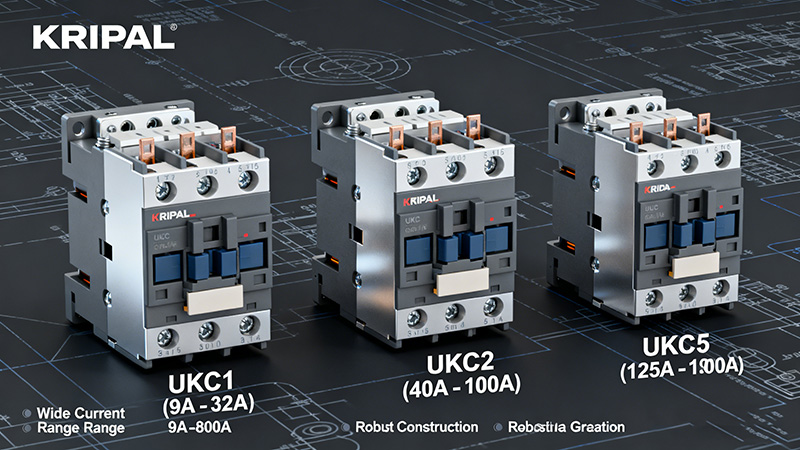

As a dedicated low-voltage electrical manufacturer, KRIPAL provides comprehensive solutions. The UKC1, UKC2, and UKC5Â series cover a wide current range from 9A to 800A, while the UKD1 DC coil series delivers excellent automation compatibility and operational stability.

Ready to Upgrade Your Industrial Control Systems?

Don’t let the wrong contactor compromise your automation reliability. Whether you need the cost-effective durability of the UKC Series or the precise, PLC-ready performance of the UKD1 Series, KRIPAL has the engineering expertise to support your project.