Cement plant

October 09, 2025

Powering Heavy Industry with Safety and Precision

In this Cement Plant Project, KRIPAL provided a complete set of industrial power distribution and connection solutions to support continuous operation in one of the most demanding industrial environments.

The cement production process requires stable, high-capacity power distribution to drive large machinery and ensure 24/7 operation under dusty and high-temperature conditions.

KRIPAL’s products were selected for their durability, waterproof performance, and high electrical safety standards, making them ideal for the cement manufacturing sector.

Cement plants operate complex mechanical systems — conveyors, kilns, crushers, and mixers — all of which depend on reliable electrical power.

To handle the heavy electrical loads, the client needed a robust and weather-resistant system that could guarantee safety, efficiency, and long-term performance.

KRIPAL engineers worked closely with the customer to design and deliver customized stainless steel distribution boxes, equipped with industrial sockets, isolators, and circuit protection modules that meet IP67 protection levels.

KRIPAL Solution

Our solution included:

- Industrial-grade stainless steel enclosures for corrosion and dust resistance.

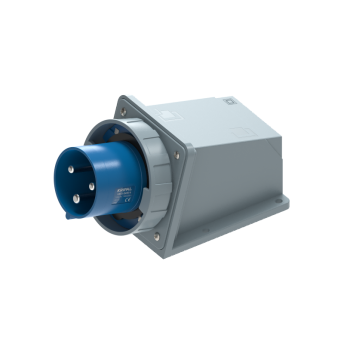

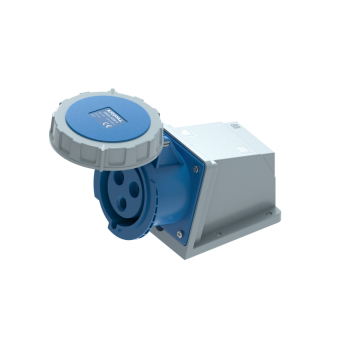

- Heavy-duty industrial plugs and sockets (16A–125A) for power connection to heavy machinery.

- Waterproof isolator switches allowing quick and safe power cut-off during maintenance.

- Built-in indicator lights and overload protection ensuring operator visibility and system safety.

All components are manufactured according to IEC standards and optimized for harsh factory environments.

The installation layout was designed to simplify maintenance and improve worker accessibility while ensuring stable power for all critical production equipment.

Project Outcome

After installation, the new KRIPAL system significantly improved electrical safety and reduced downtime caused by power failures.

The plant now operates with greater energy efficiency and reliability, supporting continuous production even under challenging conditions.

Operators praised the design for its user-friendly interface, easy cable management, and consistent performance over extended operation cycles.

Why KRIPAL

This project highlights KRIPAL’s strong capability in industrial electrical engineering and our commitment to quality, innovation, and safety.

From design to on-site application, KRIPAL ensures every product performs reliably in real-world conditions.

With years of experience serving cement plants, power stations, and heavy industries, KRIPAL continues to deliver durable, high-performance solutions trusted by clients worldwide.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

-344x344.png)