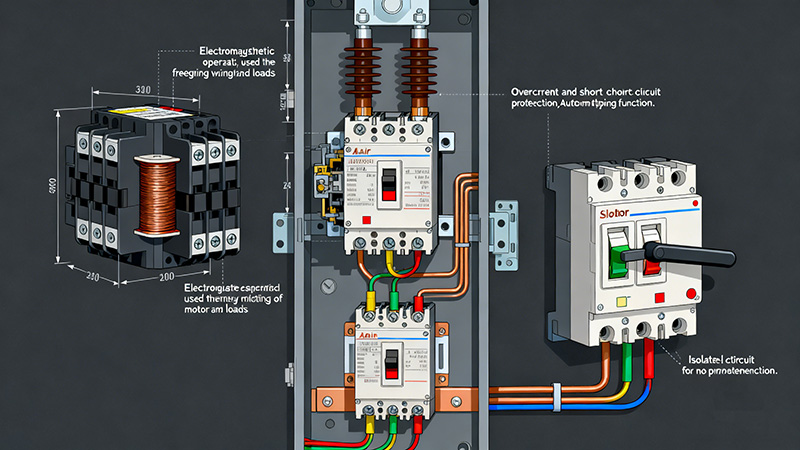

In industrial power distribution, three components form the backbone of electrical safety and control: contactors, isolator switches, and circuit breakers.

While they are often collectively called “switches,” using them interchangeably is a critical engineering error. Each serves a distinct purpose in the “Iron Triangle” of electrical systems. Confusing a load-bearing contactor with a safety isolator can lead to system failure, increased maintenance costs, or severe safety hazards.

This guide clarifies the functional differences between these devices, explains why the contactor is the core of automation, and details how they work together in a safe industrial system.

Core Principles and Functions of the Three Devices

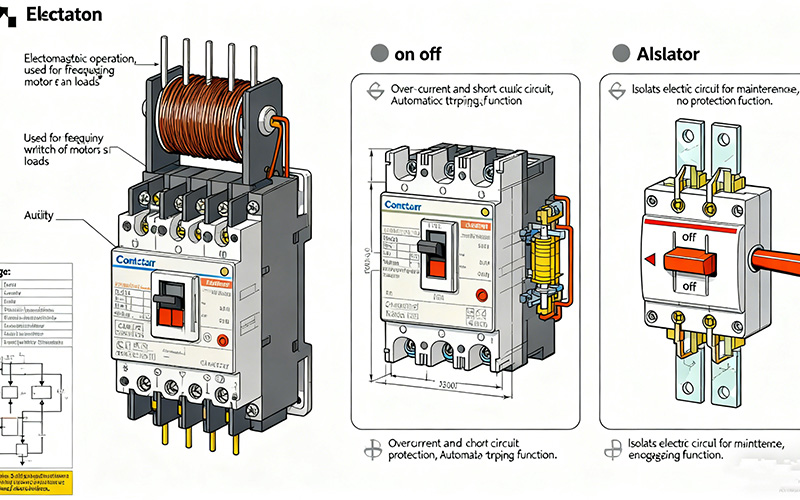

The Contactor as a High Frequency Control Expert

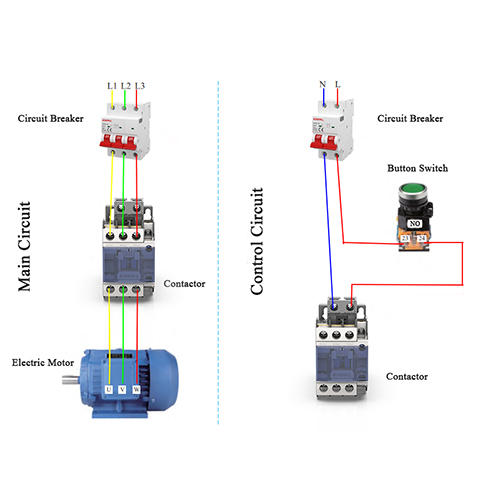

A contactor is an electromechanical switch designed specifically for the frequent opening and closing of power circuits. It acts as the primary execution element in industrial automation and is controlled remotely via a coil.

How It Works

When the electromagnetic coil is energized, it pulls the moving core against a fixed core. This action closes the contacts to power the load. When de-energized, a spring resets the core and cuts the power.

Key Characteristics

- No Protection: Unlike circuit breakers, contactors do not provide overload or short-circuit protection. Their sole focus is control.

- Durability: Built for endurance, high-quality units like KRIPAL contactors utilize silver alloy contacts to maintain conductivity over hundreds of thousands of cycles.

- Remote Integration: DC coil options allow direct compatibility with PLCs and automation relays.

The Isolator Switch as a Safety Guardian

An isolator switch, or disconnect switch, is a mechanical device used to isolate a specific section of the circuit from the power source.

How It Works

The primary function is to provide a physical, visible gap in the circuit. This ensures safety during maintenance by physically separating the downstream equipment from the power supply.

Key Characteristics

- Off-Load Only: This is a critical rule. You must never operate an isolator under load. Because it lacks arc-extinguishing chambers, opening it while current is flowing can cause dangerous arcing and equipment explosion.

- Safety: It guarantees electrical isolation for technicians working on the line.

The Circuit Breaker as a Protective Gatekeeper

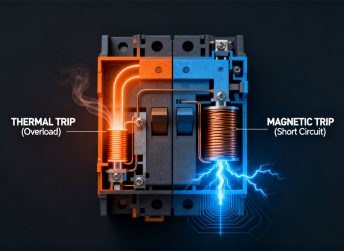

A circuit breaker is an automatic protection device that interrupts current flow during fault conditions, such as overloads or short circuits.

How It Works

It integrates thermal releases for overload detection and magnetic releases for short circuits. Under fault conditions, the breaker trips automatically to disconnect the circuit rapidly.

Key Characteristics

- Active Protection: It automatically disconnects power to save wiring and motors from damage.

- Reset Capability: Unlike a fuse, a circuit breaker can be reset after a fault is cleared, making it reusable.

Comparison of Device Applications and Roles

| Feature | Contactor | Isolator Switch | Circuit Breaker |

| Primary Function | Control (On/Off) | Safety Isolation | Protection |

| Switching Frequency | High (Thousands/hour) | Very Low (Maintenance only) | Low (Faults only) |

| Operate Under Load | Yes | NO | Yes |

| Protection Type | None | None | Overload & Short Circuit |

| Typical Application | Motors, Heaters, Pumps | Distribution Panels, PV Boxes | Main Feeders, Branch Circuits |

Why Contactors Are Irreplaceable in Automation

In automated lines, a conveyor motor may start and stop every few seconds. Circuit breakers will wear out rapidly if used for this type of switching control because they are built for static protection rather than dynamic operation. Furthermore, isolator switches cannot be used at all due to safety risks.

Only contactors are engineered to withstand the thermal and mechanical stress of high-frequency switching. For modern industry, KRIPAL offers the UKC1, UKC2, and UKC5 series. These feature silent operation and PLC-compatible DC coils ideal for Industry 4.0 applications.