Designers, installers and maintenance teams spend a lot of time thinking about protection and control. One of the most common questions in that work is how to choose between a fused disconnect and a non fused disconnect for each circuit. The choice affects protection, uptime, and the way faults are handled, so it deserves a clear explanation instead of just a quick catalogue selection.

This guide explains what a fused disconnect is, how it differs from a non fused disconnect, and how to choose the right option for your project.

- What is a fused disconnect?

- How a fused disconnect works inside

- What is a non fused disconnect

- Fused disconnect vs non fused in real use

- Fusible vs non fusible disconnect in design choices

- Fuses for disconnect switch selection

- When a non-fused disconnect makes sense

- Practical way to decide between fused and non fused

- Conclusion

What is a fused disconnect?

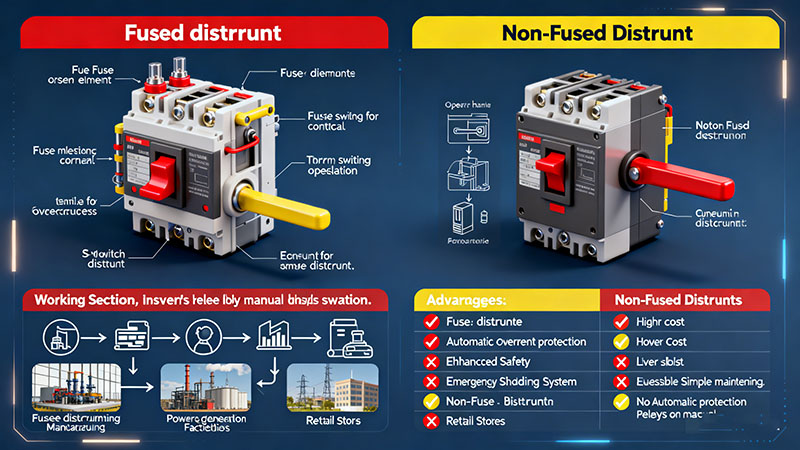

A fused disconnect is a device that combines a switch and fuses in one unit. The switch part lets you turn a circuit on and off and provides a visible isolation point. The fuse part reacts to excessive current and opens the circuit when a fault occurs. In simple words, a fused disconnect lets you isolate a circuit by hand and also protects it when current rises above the fuse rating.

How a fused disconnect works inside

Inside a fuse disconnect switch there are fixed and moving contacts that carry the normal load current. Turning the handle closes or opens these contacts. In series with those contacts sit one or more fuses. Under normal conditions the fuses simply pass current.

When a fault drives the current above the fuse rating, the metal element inside the fuse heats up, melts and breaks the circuit. This happens very fast and limits the energy that reaches cables and equipment. After that, the handle can still show an off position so that maintenance staff see a clear isolation point.

Because the switch and fuses share the same housing, fusible disconnect switches save space and provide a single place where people can see both the on off state and the condition of the fuses.

What is a non fused disconnect

A non fused disconnect has the same basic switching mechanism but no fuses, such as the Kripal UKP series from 250A to 800A. It gives a clear on position and off position for a circuit, with contacts that open and provide isolation, yet it does not include any fuse links. Protection comes from a breaker or separate fuse located elsewhere in the system.

This means a non fused disconnect mainly serves as a local isolation device. It is used when the designer wants operators to have a handle near the equipment but keeps overcurrent protection in a different panel or at the service entrance.

Fused disconnect vs non fused in real use

When people ask about non fused disconnect vs fused disconnect they are really asking where the protective element belongs.

If there is no dedicated protection on that branch, a fused disconnect brings both isolation and short circuit protection right at the equipment. If a main breaker or upstream fuse already protects the branch correctly, a non fused disconnect can be enough because the upstream device will clear faults while the local unit only handles isolation.

So fused disconnect vs non fused is not a question with one fixed answer. It depends on fault current at that point, the layout of panels and machines and how local you want fault clearing to be.

Fusible vs non fusible disconnect in design choices

The phrase fusible vs non fusible disconnect appears often in design documents. A fusible device has fuses as part of the switch. A non fusible device has only the switching function.

In a plant with high available fault current and long cable runs to motors and large machines, fusible disconnect switches at each load can protect both the machine and the connecting cables. They can also improve coordination by clearing faults locally, so that a problem on one feeder does not shut down an entire production area.

In an installation where a well sized breaker at the main board already provides strong protection and fault levels are moderate, a series of non fusible disconnect units near equipment can be the better route. They keep the layout simple and place all overcurrent settings in one central location.

Fuses for disconnect switch selection

Choosing fuses for disconnect switch applications has a strong effect on the performance of the entire circuit. The fuse rating needs to match the load and the cable while also handling the available fault current.

Matching fuse rating to load and cable

The current rating of each fuse should be selected so that normal running current passes without trouble while fault current is cleared quickly. Oversized fuses may allow overheating of cables or equipment, while undersized fuses may operate during normal start or inrush.

Fuse types for different kinds of load

Motors often use time delay fuses so that they can draw a high start current without nuisance operation. Heating loads and lighting may use fast acting fuses that respond quickly to faults because their normal current is steady and predictable. Control transformers and small auxiliary circuits usually use smaller fast-acting fuses to protect delicate windings and fine conductors.

Voltage rating and interrupt rating

The voltage rating and interrupting rating of the fuse must match or exceed the system voltage and the short circuit level at that point. This is what makes fusible disconnect switches perform well during severe faults. When the fuse element operates, the arc is controlled and the fault is cleared without damage to the switch enclosure.

Stock planning and standardisation

Stock policy also matters. Using the same fuse classes across many fuse disconnect switch positions can simplify maintenance and reduce spare part variety. This kind of standardisation helps technicians work faster and lowers the chance of fitting the wrong fuse during a repair.

When a non-fused disconnect makes sense

There are many situations where a non-fused disconnect is the better option.

Think of a panel where a main moulded case breaker already protects all outgoing circuits. Each feeder may have cable sized for that breaker. In such a layout, placing a non-fused disconnect near each machine gives a clear local on off handle without adding more protective layers. Operators get convenient control, and the maintenance team has fewer protective devices to check.

Another example is equipment that ships with its own built in protection. Many packaged units arrive with internal breakers or fuses that are tested and approved as part of the product. Adding another set of fuses at the local isolator can create confusion and make fault finding slower. In those cases, a simple non-fused disconnect in sight of the equipment can satisfy isolation rules without changing the protection scheme.

S,o fused vs unfused disconnect decisions must reflect not only electrical calculations but also how technicians will service and troubleshoot the system over time.

Practical way to decide between fused and non fused

A useful way to think about non fused disconnect vs fused disconnect is to walk through a few simple questions and answers.

Key questions

- Is there already a correctly rated overcurrent device in the supply path for this branch

- What is the available fault current at the point where you plan to install the disconnect

- How much of the plant should keep running if this branch experiences a fault

How to use the answers

- Choose a fused disconnect when

- The branch has no other dedicated protection

- The available fault current at that point is high

- You want fault clearing to happen locally at the equipment

- Choose a non fused disconnect when

- The branch is already fully protected by an upstream breaker or fuse

- You prefer to keep all protection settings in one main board

- You mainly need a simple local on off and isolation function

Conclusion

A fused disconnect joins a switch with fuses so that one device can isolate and protect a circuit at the same time. A non fused disconnect removes the fuses and focuses purely on switching, leaving protection to other devices.

When you select fuses for disconnect switch duty with care and place fusible disconnect switches only where they add real value, your panels become easier to understand, easier to service and better suited to the demands of modern power distribution.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.