Many projects and electrical systems require more than standard circuit breakers. An OEM circuit breaker or a custom moulded-case circuit breaker (MCCB) may suit particular load conditions, installation constraints or client requirements better than off-the-shelf devices. Custom manufacturing enables flexibility in ratings, features, certifications and branding.

Why a Custom or OEM Circuit Breaker Makes Sense

Standard breakers serve common needs. In some situations standard options do not match what a project demands. A custom or OEM breaker allows specification of voltage rating, current capacity, number of poles, breaking capacity and trip behavior to match actual supply and load conditions. For motor‑heavy installations or renewable energy systems, custom trip settings or DC‑rated insulation can prevent nuisance tripping or failure.

Custom manufacturing also gives flexibility in mechanical design. Breakers can be built to fit specific panel layouts or device enclosures. Custom labeling, branding, packaging or terminal configuration help integrate breakers into bespoke systems or OEM equipment. For projects with export or compliance demands, certification requirements can be built in from the start.

Finally, custom breakers deliver consistency across multiple installations. When a manufacturer builds to customer specification, every unit matches the first one. This uniformity simplifies maintenance, supports replacement consistency and helps bulk procurement for large or repeated projects.

What Custom Breaker Manufacturing Involves

A circuit breaker factory offering OEM or custom solutions follows several stages to deliver a tailored product:

- Gathering detailed requirements from the customer including system voltage, current demand, environment and load type

- Engineering a design or adapting an existing breaker frame to meet those requirements, including trip units, arc‑extinguishing design, materials and mechanical layout

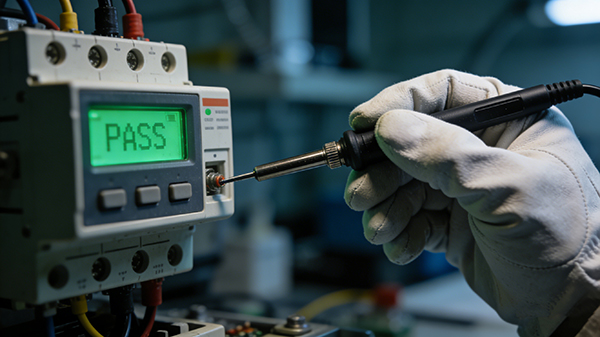

- Producing prototypes and conducting tests under load, overload and fault conditions to validate performance

- After testing and approval, launching mass production under strict quality control standards, ensuring each breaker meets specification and regulatory standards

- Offering support for markings, packaging, certifications or compliance documentation for export or project needs

Common Uses of OEM or Customized MCCBs

Custom or OEM circuit breakers are often chosen in the following situations:

- Industrial or commercial systems where standard breakers cannot handle high current or fault levels

- Renewable energy installations and DC systems that require breakers optimized for non‑standard voltages or specialized arc suppression

- Equipment or panels built for export, requiring compliance with international standards or certifications

- Motor control centers or installations with frequent startup surges, demanding tailored trip curves or adjustable protection settings

- OEM equipment where breakers must integrate mechanically with custom housings, busbars or control panels

What Buyers Should Specify for Custom Breakers

When commissioning a custom or OEM breaker, providing clear and full specifications helps ensure the final product matches expectations. Key items to define include:

- Supply voltage type (AC or DC) and system voltage

- Expected continuous current and maximum fault current at installation point

- Number of poles, breaker frame size and mounting or terminal configuration

- Trip behavior or curve type (thermal, thermal‑magnetic, electronic, adjustable)

- Required certifications or standard compliance, if any

- Mechanical layout constraints, environmental or installation conditions

This clarity helps the manufacturer design and build a breaker tailored to real conditions instead of guessing from a generic model.