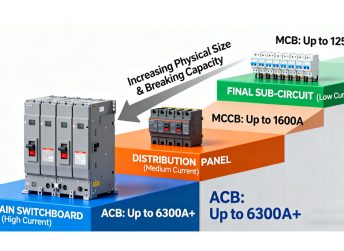

When a building, factory or large facility requires a main power supply that feeds multiple sub‑circuits, choosing the right main incomer protection becomes key. For high current, heavy load, complex distribution systems, an Air Circuit Breaker often serves as the best choice. This article examines what an ACB is, why it suits main source protection, and what to check when selecting one.

An Air Circuit Breaker is a type of circuit breaker that uses air as the medium for arc extinguishing when contacts open under fault conditions. Compared to smaller breakers used in lighting or small‑load circuits, an ACB supports much higher current ratings and has greater capability to interrupt fault currents. Typical applications of ACBs are in low‑voltage industrial or commercial distribution systems.

An ACB includes robust internal structure: main contacts, arcing contacts, arc chute (or arc extinguishing chamber), a trip unit, and an operating mechanism. When normal current flows it passes through main contacts; under fault or overload the trip unit triggers opening, and arc contacts plus arc chute extinguish the resulting arc safely.

What Sets ACB Apart from Smaller Breakers

Higher Current and Fault‑Current Capacity

ACBs handle large currents and high prospective fault currents. Where miniature breakers or molded‑case breakers reach their limits, ACBs continue to perform reliably. Their design supports main incoming feeders, transformers, and heavy‑load feeders without risk of failure under high fault stress.

Strong Arc‑Quenching and Mechanical Stability

When contacts open under fault conditions, an arc forms. ACBs are designed to extinguish this arc via arc chutes that cool, stretch, or divide the arc until it dies out. This arc‑quenching design helps avoid contact damage and ensures safe interruption. Structure and materials used in ACBs give mechanical durability suited for frequent switching or heavy current flow.

Suitable for Complex or Three‑Phase Power Distribution

In three‑phase systems with heavy loads, long feeders, or central distribution panels, ACBs offer stable and reliable protection. Their capacity and robustness make them suitable as the first line of protection for entire power distribution systems feeding multiple sub‑circuits or heavy equipment.

Common Use Cases for ACBs

Air Circuit Breakers often appear in the following situations:

- As the main incomer breaker for large buildings, factories, or commercial complexes.

- Feeding transformers, main distribution boards, heavy‑load feeders, or main buses.

- Protecting three‑phase, high‑power motors, large loads or multiple sub‑panels.

- Industrial plants where load is heavy and fault current potential is high.

In these scenarios ACBs give a reliable way to manage high current supply and protect system integrity under fault or overload conditions.

What to Check When Selecting an ACB?

Current Rating and Breaking Capacity

First confirm the maximum continuous load current and the highest possible fault current in your system. Choose an ACB whose rated current and interrupting capacity safely cover both. Undersized breaker may fail under fault; oversized breaker may increase cost and reduce sensitivity.

Contact and Arc‑Extinguishing Design Quality

Ensure the ACB uses durable main and arcing contacts. Check that arc chute design suits expected fault current levels. Good arc‑quenching helps maintain long service life and safe operation under repeated fault conditions.

Phase Compatibility and System Voltage

Match the ACB to your system’s voltage and phase configuration (single phase, three phase, etc.). Make sure the breaker’s specifications align with busbar layout, supply voltage, and load type.

Installation Environment and Maintenance Requirements

Industrial or commercial environments may have high temperature, dust, humidity or vibration. ACB must have suitable insulation rating, enclosure design, and maintenance accessibility. The installation layout should provide enough space around the breaker for safe operation, inspection and servicing.

Ease of Operation and Safety Features

Since an ACB may act as a main switch, it should allow reliable manual or remote operation. Ensure locking mechanisms, position indicators and safe isolation features are present if required.

Why ACB Works Well for Main Incoming Protection

An Air Circuit Breaker’s combination of high current handling, robust arc‑quenching, mechanical stability and compatibility with complex systems makes it suitable for main incoming protection. It handles heavy load demand, offers safe and reliable fault interruption, and supports safe isolation for maintenance or system modifications.

Using a small breaker where system demand is high may lead to nuisance trips, failure under fault, or reduced protection effectiveness. ACB removes that risk and ensures supply reliability and safety.

Summary

An Air Circuit Breaker brings high‑capacity, reliable protection for main supply lines in industrial, commercial or large installations. Its design supports high current, high fault current capacity, arc extinguishing, mechanical strength and flexible operation. A properly chosen ACB ensures stable, safe power distribution for complex systems.

For a broad selection of ACBs and other industrial-grade circuit breakers suitable for large‑scale installations, contact the Kripal team to explore compatible models for your project.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.