The two-month 2025 Quality Month program officially concluded on November 17. Under the theme âPursuing Excellence, Quality First,â the event adopted a dual approach of training and competition, offering a series of targeted sessions and skill-based challenges.

- Quality Training Strengthening Fundamental Competence

- Skill Competitions: Putting Knowledge Into Practice

- Knowledge Competition Testing Theoretical Mastery

- Awards Ceremony Celebrating Excellence

- Leadership Message Reinforcing the Commitment to Quality

- Looking Ahead Continuing the Journey of Quality Excellence

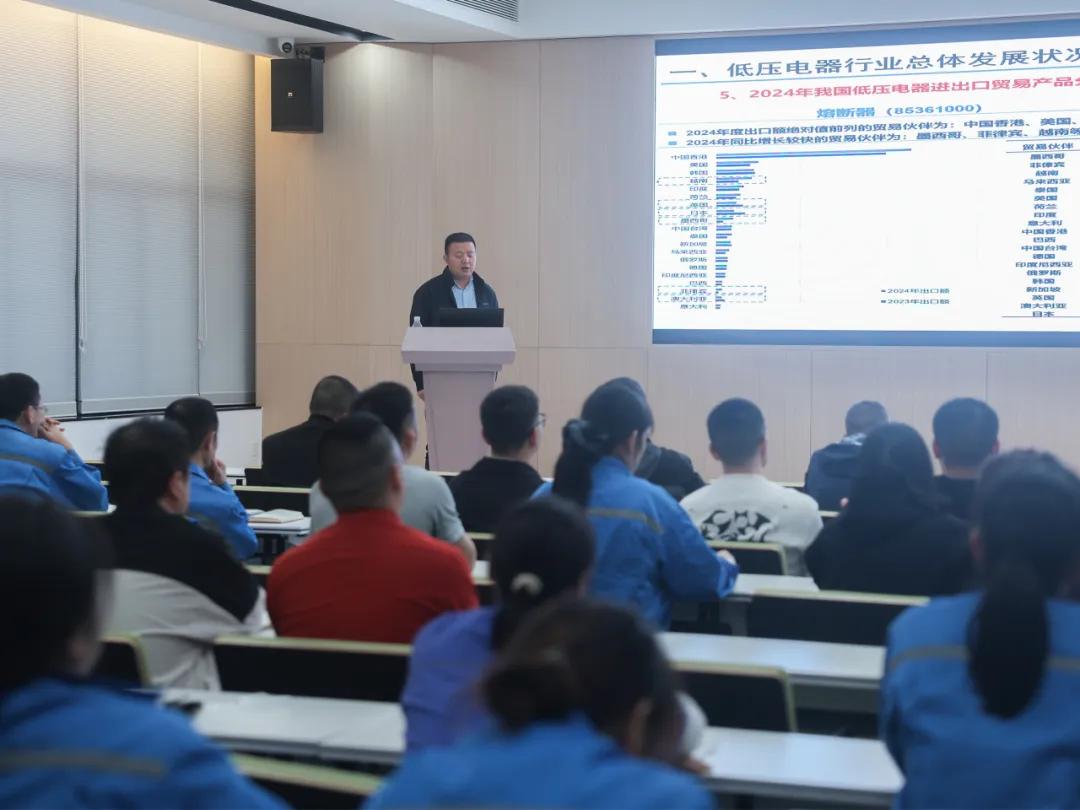

Quality Training Strengthening Fundamental Competence

Beginning on September 4, the company organized multiple rounds of quality-themed training sessions. The courses covered topics such as 6S on-site management, product process specifications and ISO 9001 system standards. Through a combination of case studies and hands-on exercises, employees deepened their theoretical understanding and strengthened their professional competence.

Skill Competitions: Putting Knowledge Into Practice

From October 21 to 24, a series of position-specific skill competitions were held in the waterproof electrical workshop. Events included label defect inspection, label alignment challenges and screw-torquing skills.

Label Defect Inspection

- First Place: He Wenning

- Second Place: Hu Dengpiao, Zhao Li

- Third Place: Zhan Shuangling, Li Shixue, Shu Kaixu, Tang Lingling

Label Alignment Challenge

- First Place: Fan Cunliang

- Second Place: Yang Yunxia, Li Shimin

- Third Place: Chen Chengyuan, Wang Keke, Cheng Yang

Copper Tube Precision Challenge

- First Place: Hou Chenchen

- Second Place: Xia Juan, Wu Lingwei

- Third Place: Shang Huanhuan, Zhou Baocui, Chen Junmei

Knowledge Competition Testing Theoretical Mastery

A quality knowledge quiz was held on November 14 in a timed, on-site format. The competition assessed employeesâ understanding of quality systems, process standards and related theoretical content. Contestants performed confidently, showcasing strong foundational knowledge. Wu Qinghai earned first place with a perfect score.

Awards Ceremony Celebrating Excellence

On the morning of November 16, the company held the Quality Month closing and awards ceremony. Quality Manager Zhong Qiubo summarised the overall progress and achievements of the 2025 Quality Month program. The list of competition winners was then announced, followed by the presentation of awards by members of the Quality Month event committee.

Leadership Message Reinforcing the Commitment to Quality

Following the awards ceremony, General Manager Lin delivered an important speech. He noted that Quality Month was not only a concentrated period of skill development and knowledge enhancement, but also a significant milestone in the companyâs quality culture. He emphasised that quality management must remain continuous, systematic and innovative.

He encouraged all employees to integrate excellence into daily work and put quality-first principles into action. By doing so, the company will continue elevating its quality management capabilities and strengthening the KRIPAL brand.

Looking Ahead Continuing the Journey of Quality Excellence

Although the 2025 Quality Month has come to an end, KRIPAL Electricâs commitment to quality improvement continues. The company will further refine its training mechanisms, promote best practices and deepen its quality culture. The pursuit of zero defects will remain a shared goal for every employee, providing sustained momentum for the companyâs long-term development.

The competition was intense yet orderly. Contestants performed with focus and precision while judges evaluated each step carefully to ensure fair scoring. In the label defect inspection event, participants achieved a remarkable 98.26 percent compliance rate with the UKC1-63 label design standards, demonstrating the effectiveness of the prior training.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.