In the world of industrial automation, electric motors are the workhorses driving everything from conveyor belts to HVAC fans. However, these expensive assets face a constant threat: overcurrent.

Without proper protection, a simple mechanical jam or a voltage spike can cause a motor to overheat, leading to insulation failure, costly downtime, or even fire hazards. This is where the Overload Relay (OLR) becomes indispensable.

This guide will delve into its types, operating principles, and industrial applications.

What is an Overload Relay?

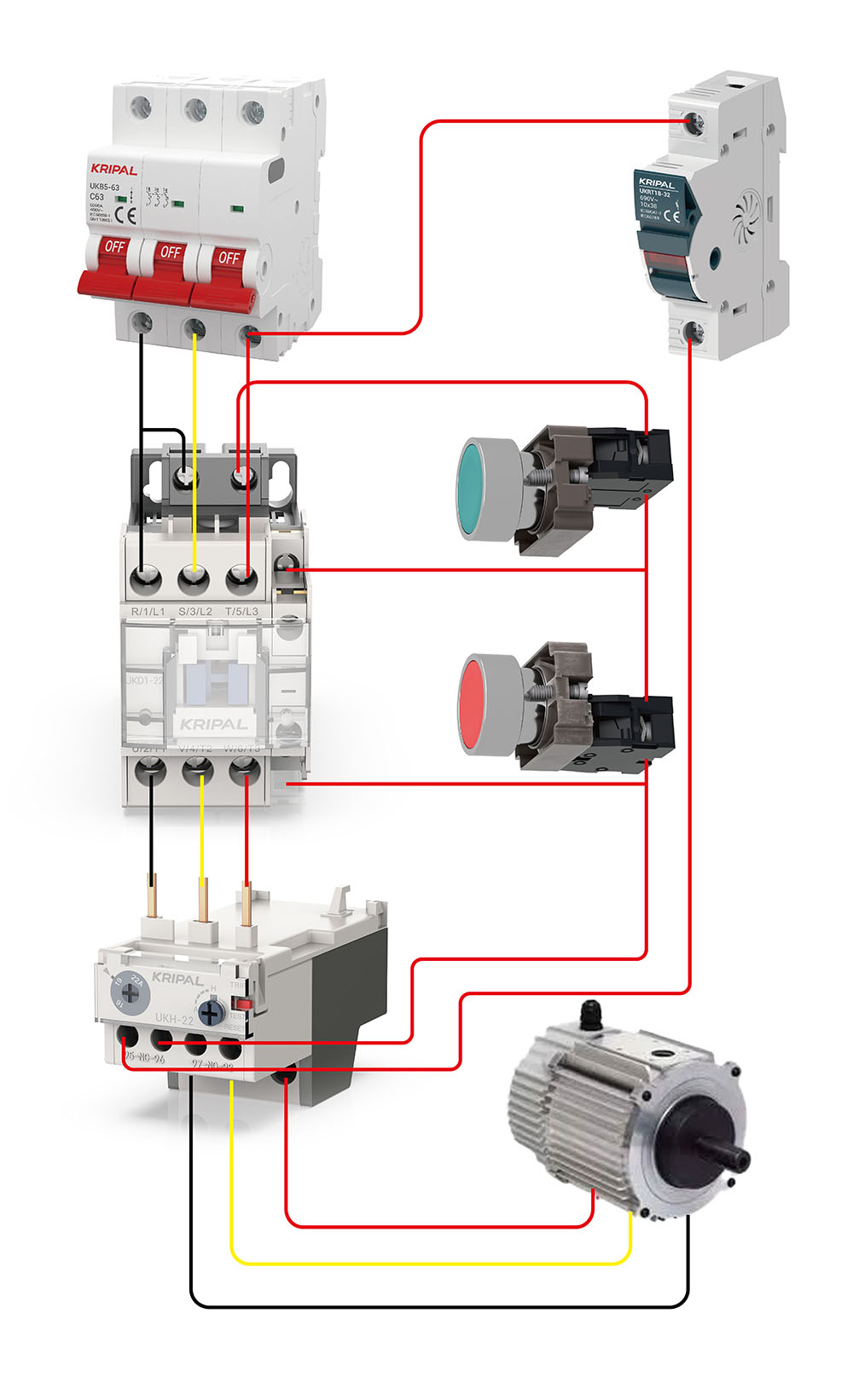

An overload relay is an electrical protection device designed to prevent damage to motors and circuits caused by excessive current (overload). Unlike a circuit breaker, which protects against short circuits, an overload relay protects against prolonged overcurrent that causes overheating over time.

When the relay detects an electrical load exceeding the preset limit for a specific duration, it mechanically cuts off the power to the contactor coil, safely stopping the motor.

The Three Main Types of Overload Relays

While the goal is the same, different technologies are used to detect overloads:

| Type | Working Principle | Best Application |

| Thermal Overload Relay | Uses a bimetallic strip that deforms when heated by current. | Cost-effective standard motor protection. Widely used in industrial and building sectors. (e.g., KRIPAL UK Series). |

| Magnetic Overload Relay | Uses an electromagnetic coil mechanism to trip. | Applications requiring high-speed fault response (less common for standard motors). |

| Electronic Overload Relay | Uses microprocessors to monitor current in real-time. | Precision automation systems requiring advanced data monitoring. (Note: KRIPAL is currently developing next-gen electronic models). |

KRIPALÔÇÖs Focus: The KRIPAL UK Series┬á(including UKH Standard and UKK Phase-Failure models) focuses on the proven Thermal technology. By optimizing the bimetallic structure, we balance high protection precision with exceptional cost-performance ratios.

How Does a Thermal Overload Relay Work?

The core mechanism of a thermal overload relay is based on the Thermal Bimetallic Strip.

- Heat Generation: When the motor runs, current flows through heating elements inside the relay.

- Deformation: If the current exceeds the rated value (overload), the heat causes the bimetallic strip to bend.

- Tripping: Once the bending reaches a specific threshold, it triggers the mechanical latch.

- Protection: This action opens the Normally Closed (NC) auxiliary contact ´╝ë, cutting power to the contactor coil and stopping the motor immediately.

The “Phase Failure” Advantage

Standard relays might miss a “Phase Loss” where one of the three power lines fails. The KRIPAL UKK Model features a built-in differential mechanism. If one phase is lost, the internal mechanism detects the imbalance and trips the relay faster than a standard overload, preventing the motor from burning out due to single-phasing.

Industry Applications & KRIPAL Solutions

Where should you install these relays? Here is a quick guide:

- Manufacturing & Automation

For the backbone of industrial production, such as conveyor belts, compressors, and industrial fans, reliable motor protection is essential to prevent costly downtime. The KRIPAL UKH Standard Type is the ideal solution for these rigorous environments. With an expansive current range of 0.1A to 630A, it integrates seamlessly with IEC standard contactors, providing versatile and robust protection that keeps production lines running smoothly.

- HVAC Systems

HVAC applications, including cooling tower fans and circulation pumps, are frequently exposed to grid fluctuations that can lead to damaging phase imbalances. The KRIPAL UKK model is specifically engineered to address these challenges. By featuring built-in Phase Failure Protection, the UKK provides an extra layer of security against phase loss, ensuring stable climate control and preventing motor burnout in unstable power conditions.

- Water Treatment & Irrigation

Critical fluid management equipment, such as submersible and booster pumps, operates in challenging conditions that demand high durability. KRIPAL relays are designed with IP20 protection, making them exceptionally suitable for the humid environments typical of water treatment plants and agricultural irrigation systems. This robust design ensures consistent performance during long-term, continuous operations where reliability is paramount.

- Building Distribution

In modern building infrastructure, safety and regulatory compliance are non-negotiable for critical loads like elevator drives and fire pumps. KRIPAL relays are fully compliant with the rigorous IEC 60947-4-1 standard. This certification guarantees that your essential building distribution systems meet strict international safety codes, providing peace of mind that safety-critical equipment will function reliably when it matters most.

How to Select the Right Overload Relay

Choosing the wrong relay can lead to nuisance tripping or motor damage. Follow these three steps:

1. Match the Current (FLA)

The most fundamental step is ensuring the relay’s setting range encompasses the motor’s Full Load Amperage (FLA). As a general engineering rule of thumb, you should adjust the relay dial to approximately 115% to 125% of the motor’s rated FLA. This buffer accommodates normal operational fluctuations while ensuring the device triggers timely protection during genuine overload conditions.

2. Select the Trip Class

You must select a trip class that matches your application’s starting characteristics to avoid nuisance tripping. Class 10 is the standard choice for general-purpose applications like pumps and fans, designed to trip within 10 seconds or less at 600% overload. Conversely, for high-inertia loads that require longer startup times, you should opt for Class 20, which allows for a longer duration of high current during the motor’s spin-up phase without tripping.

3. Check for Phase Failure Requirement

For critical three-phase motor applications, particularly those situated in areas with unstable power grids or at the end of long transmission lines, standard thermal protection may not be enough. In these scenarios, it is highly recommended to prioritize the KRIPAL UKK Series. This series provides an extra layer of differential protection specifically designed to detect phase imbalances and single-phasing events that could otherwise silently damage the motor windings.

4. Installation Compatibility

Finally, verify that the physical form factor suits your control panel’s layout and assembly requirements. The KRIPAL UK Series is designed for maximum versatility, capable of mounting directly onto standard DIN rails. Furthermore, it integrates seamlessly with KRIPAL contactors┬á┬áto form a compact, unified motor starter assembly that saves panel space and simplifies wiring.

Why Engineers Choose KRIPAL

- High Reliability: Precision-calibrated bimetallic strips ensure high repeatability and a long operational lifespan.

- All-in-One Protection: The UKK model offers Phase Failure detection without needing expensive external sensors.

- Global Compliance: We hold complete CE, RoHS, and UL certifications, making our products ready for the global market.

- Cost-Efficiency: Reduce maintenance costs and downtime with a durable product priced competitively.

Conclusion

While technology evolves, the Thermal Overload Relay remains the industry standard for motor protection due to its simplicity, reliability, and cost-effectiveness.

When selecting protection for your machinery, do not compromise. Ensure your choice meets international standards like IEC 60947-4-1 and matches your specific load characteristics.

Ready to safeguard your motors? Explore the KRIPAL UK Series (UKH Standard & UKK Phase-Protection) today. We deliver trusted solutions that minimize downtime and maximize safety.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.