Many people hear the term isolator for the first time and wonder what it really does. Search queries such as what is isolator, isolator means and isolator switch all point to the same idea. An isolator is a device that gives clear and secure separation between a power source and the equipment it feeds so that work can be carried out without risk from live parts.

This article explains what an isolator switch is, how it works, where isolation switches are used and why choosing a Kripal isolating switch can make daily operation and maintenance smoother.

What is an isolator in simple terms

In the most direct sense, isolator means a switch that disconnects a circuit from its source and holds that circuit in an open state. When the isolator is open there is a safe gap between live parts inside the device. No current should flow and a technician can treat the downstream side as de energised after proper testing.

You may see the phrase isolator define expressed in many guides as a mechanical switching device that disconnects all live conductors in a circuit and provides visible or clearly indicated separation. While the wording changes from one source to another, the purpose stays the same. The isolator switch is there so that a person can see or trust that a circuit is fully off before starting work.

This is very different from a protective device such as a fuse or a circuit breaker. Those devices react to faults. The isolator exists so that people can deliberately open the circuit and keep it open during inspection, cleaning or replacement of components.

How an isolator switch works inside

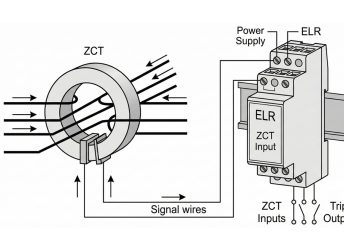

From the outside an isolator switch appears simple. There is usually a rotary handle or a lever with two positions marked on and off. When you move the handle to off a set of contacts inside the body of the switch separate by a defined distance. This distance and the insulation around the contacts are chosen so that the air gap can withstand the applied voltage.

Many modern isolation switches use a snap action mechanism. Even if the user moves the handle slowly the internal contacts open quickly and decisively. This reduces the time during which an arc can form as the contacts part. Some designs include arc chutes or shields to guide and cool any small arc that appears when a load is disconnected.

The internal parts are designed for mechanical strength and long life. An isolator may be operated many times over many years. The linkage, bearings and contacts must keep their alignment so that the same safe separation is achieved every time the switch is opened.

Why isolation switches matter for safety and maintenance

In any installation with more than a few loads there will be regular tasks such as tightening connections replacing motors cleaning fans or changing control components. These tasks require the power to that equipment to be off and secured.

This is where isolation switches have a central role. A local isolator switch near the equipment allows a person to

- Open the supply to that specific load without affecting the rest of the site

- Apply a padlock or other lock off device in the off position

- Confirm with a test meter that the part of the circuit to be worked on is not live

By following these steps maintenance teams can work with clear confidence that the energy source has been removed. The isolator switch becomes the visible marker that a circuit is under safe working conditions.

In urgent situations a nearby isolating switch can also be used to stop a motor or other device quickly. For that reason the handle is usually coloured in a way that stands out and is placed where it can be reached without delay.

Where isolators are used in practice

| Application | Typical location of isolator switch | Purpose of isolation | Typical isolation switch style |

| Motor and pump circuits | On the wall or frame next to the motor fan or pump | Allow safe cleaning belt changes and motor replacement for one load | Three pole or four pole rotary isolator in a compact enclosure |

| Distribution and sub boards | Near the main handle of the board where it is easy to see | Shut down the entire board so internal wiring and devices can be serviced | Panel mounted load isolator switch with front operated handle |

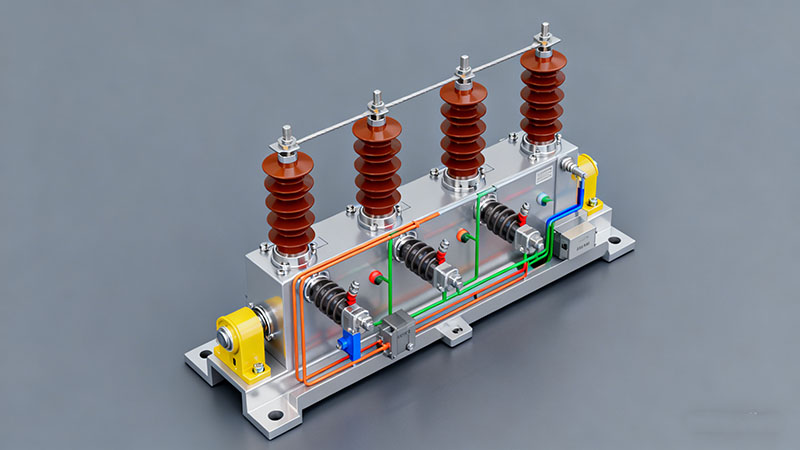

| Solar photovoltaic arrays | Next to string boxes inverters or on outdoor mounting frames | >Disconnect DC strings before work on panels cables or inverters | Dedicated DC isolator switch with high DC voltage rating |

| Air conditioning and ventilation | Close to condensers roof fans and air handling units | Enable safe service of fans and compressors while other plant runs | Weatherproof isolation switches with clear on and off markings |

| Changeover and backup supply | Near generators transfer panels and incoming supply points | Separate loads from one source before connecting another source | Manually operated changeover isolator with stable positions for each source |

| Industrial machines and lines | On machine frames or nearby pillars within clear view | Provide a local point to secure power off during tooling changes and guard removal | Lockable isolating switch sometimes used together with an emergency stop device |

Why choose a Kripal isolating switch

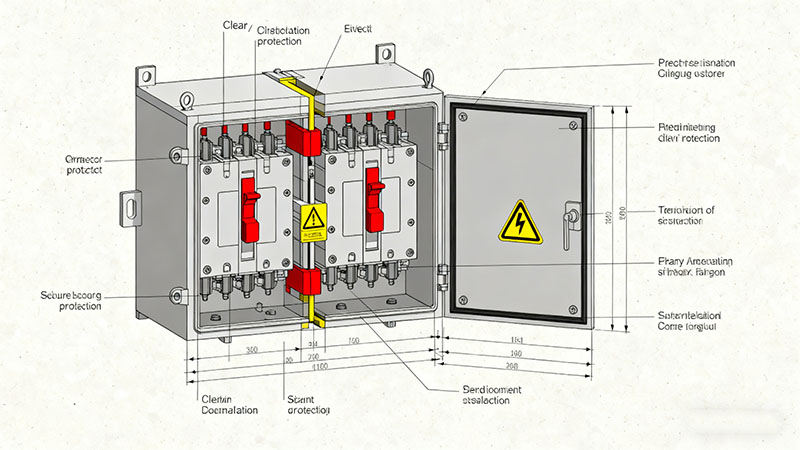

Once you understand what is isolator and how isolation switches work, the next step is choosing a product range that fits real world conditions. Kripal is a specialist maker of low voltage and waterproof equipment with many product lines covering isolator switch solutions for indoor and outdoor use.

Range for indoor and outdoor use

Kripal offers load isolating switch products such as the UKP, UKPN, UKPWÂ and UKPA series. These devices are described as high quality to meet isolation and insulation requirements while complying with standards such as IEC EN 60947.

Kripal’s UKPWÂ series waterproof isolation switches are built for outdoor duty and diverse applications. They are available in 2P, 3P, 4P, and 5P versions, with current ratings from 10A to 150A. All models provide generous wiring space and feature base mounting for easy termination.

Coverage of both AC and DC circuits

Modern installations often mix motors and lighting with solar arrays and storage. Kripal answers this need with AC load isolating switch products and dedicated DC isolator switch units for photovoltaic use. The DC isolator series is presented with voltage ratings up to 1500V DC and includes lockable handles for secure off positions in solar circuits.

Focus on insulation performance and tested design

The Kripal UKP load isolating switch range is described as providing effective isolation and insulation performance and as being improved continuously. Compliance with recognised standards gives users confidence that contact gaps, insulation distances, temperature rise and endurance have been checked under formal test routines.

Practical details for installers

Many Kripal isolation switches include clear on and off markings and enclosures shaped to resist dust and water. UKF series descriptions highlight impact resistant bases and lids together with seals that help maintain an ingress protection rating in demanding conditions.

Base mounting and generous wiring space make it easier for installers to route and secure cables neatly, which supports long term reliability.

Good practice when using an isolator

Even the best designed isolator switch gives full benefit only when used with care.

- Mount each isolator close to the equipment it controls and use clear matching labels on both device and load.

- Before work open the related isolator switch apply lock and tag if required and test with a suitable meter to confirm the conductors are not live.

- After work remove tools close covers remove locks and return the isolator to the on position.

- Inspect isolators regularly for signs of overheating stiff or loose operation and faded labels and plan repair or replacement in good time.

Final thoughts and next steps

For anyone still wondering what is isolator, the short answer is that it is the device that tells you with confidence that a circuit is truly off. Phrases such as isolator means, isolator define, isolation switches and isolating switch all describe this same idea. By understanding how these devices work and where they are used in practice, designers and technicians can build installations that are easier to maintain and smoother to operate throughout their service life.

If you are planning a project and would like pricing, data sheets or sample support for Kripal isolator switch products, send an inquiry with your voltage, current, pole number and quantity details. We are glad to help.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.