When inspecting or selecting an MCCB, pay attention to the following:

Current rating and frame size: MCCBs are classified by their rated current capacity and frame size. Choose a model that matches the expected continuous load and peak demand. Underrated breakers risk nuisance trips or failure under load; overrated breakers may reduce sensitivity to fault conditions.

Interrupting (breaking) capacity: Industrial circuits may see high fault currents. MCCB must have a breaking capacity high enough to interrupt expected short‑circuit or fault currents without damage.

Trip unit adjustability: If circuits power motors, compressors or equipment with inrush current, adjustable trip settings help avoid false trips while still protecting against overloads or faults.

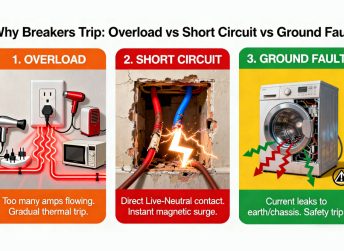

Thermal‑magnetic mechanism: Provides combined protection against sustained overloads (thermal) and instantaneous faults (magnetic). This dual protection suits varied industrial load conditions.

Arc‑extinguishing design: Reliable arc‑chutes or arc‑quenching elements help extinguish arcs when breaker operates under fault — crucial to avoid contact damage or fire risk.

Construction quality and durability: Industrial use often means more cycles, heavier loads and harsher conditions. A well‑designed MCCB with sturdy materials and build quality delivers long‑term reliability.

Where MCCBs Are Commonly Used in Industrial Settings

In factories, MCCBs often appear in:

- Main distribution boards feed the entire production lines or facility power

- Sub‑panels powering motor groups, HVAC systems, control systems, and machines

- Motor control centers delivering power to heavy motors and starting circuits

- Protection of transformers, compressors, heaters, pumps, and heavy loads

- Backup or auxiliary power circuits, UPS feeders, or lighting for industrial buildings

Because industrial power demands fluctuate and fault potential may be significant, MCCBs help manage safety and reliability across all these applications.

What to Check When Designing with MCCB?

When integrating MCCBs into an electrical system:

- Check expected current load, including steady‑state and startup peaks. Factor in future expansion or additional loads. Select a breaker whose current rating, breaking capacity and trip settings matchthe load profile.

- Ensure wiring, busbars, terminals, and panel layout match breaker specifications. Proper connection quality and suitable conductor size matter for safe operation.

- Consider environmental factors. Industrial sites may have high temperature, dust, moisture or vibration. Choose MCCBs rated for environment, with adequate enclosure and insulation.

- Plan for maintenance access and safe isolation. MCCB installation should allow safe manual switching off, inspection, and resetting if needed.

If loads include motors or variable devices, configure trip settings or use adjustable models to handle inrush currents without false trips.

Conclusion

MCCB circuit breakers suit industrial and heavy‑duty electrical applications where load and fault conditions exceed what small breakers can handle. Proper selection, wiring and installation ensure safe, stable, and flexible power distribution in demanding environments.

For a full range of industrial‑grade circuit protection equipment and expert advice tailored to factories, panels or electrical installations, contact the Kripal team and explore their offerings.