Are you looking to control high-power electrical loads like motors, lighting, or heating elements? An electrical contactor is the essential component you need. In industrial automation, contactors are the backbone of control systems, offering reliability, safety, and the ability to handle frequent switching operations.

In this comprehensive guide, we will break down the working principles, compare AC vs. DC structures, explore the 6 main types, and provide the formulas you need to select the right model.

What is a Contactor?

Before diving into the types, let’s clarify the definition. At its core, an electrical contactor is an electromechanically operated switch designed to toggle power circuits. While it shares a lineage with the common relay, a contactor is specifically engineered to handle significantly higher current loads.

The primary function of a contactor is to bridge the gap between low-power control signals and high-power execution. By using a low-voltage control signal, operators can safely manage high-voltage, high-current circuits from a distance.

Key Functional Advantages

- Galvanic Isolation: It provides a safety barrier between high-voltage power circuits and the human operator.

- High-Frequency Cycling: Engineered for durability, contactors can withstand thousands of switching cycles per hour.

- Arc & Overload Management: Designed with specialized contact materials and arc-suppression features to protect the integrity of the electrical system.

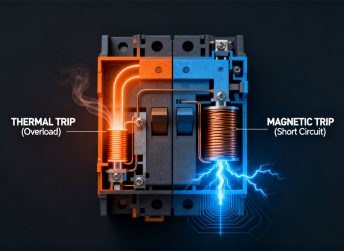

Contactor vs. Relay vs. Circuit Breaker

In the field, it is common to confuse these components. However, their roles are distinct:

- Contactor vs. Relay: While both are switches, contactors are heavy-duty components designed for high-power “load” circuits. Relays are generally used for lower-power logic and signal switching.

- Contactor vs. Circuit Breaker: A circuit breaker is a passive safety device designed to interrupt a circuit during a fault. A contactor is an active control device designed for routine switching. In a robust system, these two work in tandem to provide both operational control and safety protection.

In a robust system, these two work in tandem to provide both operational control and safety protection. However, understanding the specific roles of each component is key to system design.

[Recommended Reading: A Comprehensive Breakdown of Contactor vs. Circuit Breaker vs. Isolator Switch]

How Does a Contactor Work?

At its core, a contactor functions through the interaction of three main components: a coil, a movable armature, and electrical contacts. When the coil is energized, it generates a magnetic field that attracts the armature, mechanically closing the contacts to complete the circuit and power the load. Conversely, when the coil is de-energized, a return spring forces the armature back to break the connection, while integrated arc suppression mechanisms quickly extinguish any electrical arcs formed during disconnection to protect the device from damage.

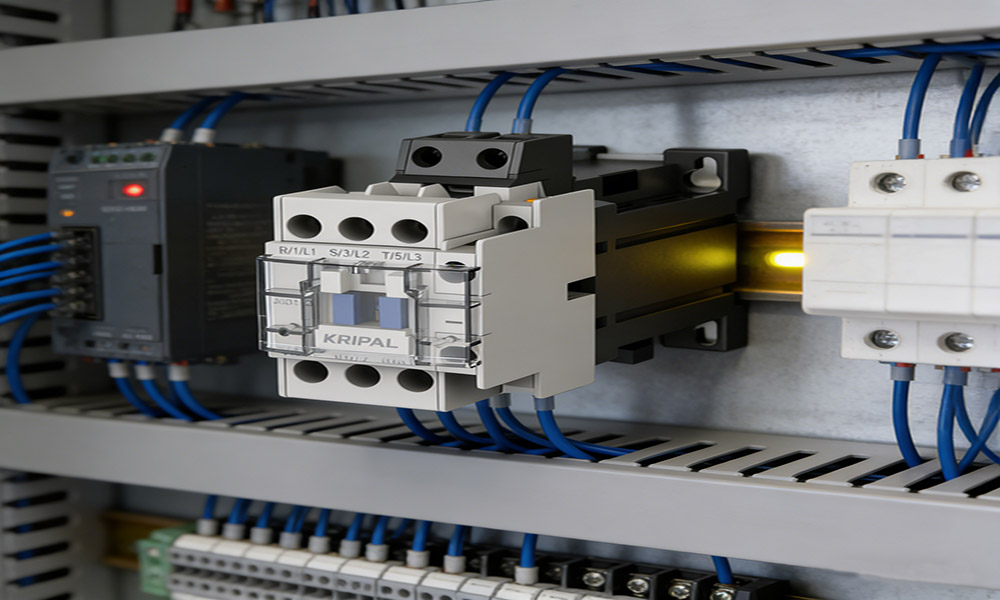

KRIPAL 6 Main Types of Contactors

Choosing a contactor shouldn’t be a trade-off between quality and cost. KRIPAL has spent years refining a product portfolio that covers the full spectrum of industrial, domestic, and construction needs. From high-frequency industrial switching to silent home automation, our six core categories are designed to solve your specific power-control challenges.

1. AC Contactors

As the most widely utilized switching solution in both residential and industrial sectors, AC Contactors are the standard for managing Alternating Current (AC) circuits. These devices are engineered with a laminated iron core specifically designed to reduce eddy current losses, ensuring the stable and efficient control of motors, fans, and pumps. KRIPAL’s AC Contactor lineup provides a massive current-rated range from 6A to 800A, allowing you to scale from light commercial applications to heavy-duty industrial loads with ease.

- Best For: Three-phase asynchronous motors, air compressors, conveyor systems, general industrial machinery, and standard lighting or heating circuits.

- Key Engineering Advantages: High cost-effectiveness, exceptional versatility, and the inclusion of a shading coil to eliminate vibration (chatter) during operation, ensuring a longer mechanical lifespan.

Our core offerings including the high-performance UKC1, UKC2, and UKC5 series are designed to meet diverse installation requirements. Beyond technical specs, we offer various color options, allowing you to maintain visual consistency and professional aesthetics.

2. DC Coil AC Contactors

A highly efficient hybrid, these are fundamentally AC contactors designed to switch AC power loads but utilize a DC-driven coil for activation. By replacing the traditional AC coil with a DC counterpart, these contactors offer a more stable and silent operational profile.

- Best For: Automation control cabinets, marine electrical systems, elevator control, and precision equipment where electromagnetic interference (EMI) or noise must be minimized.

- Key Advantages:

- Silent Operation: Eliminates the “hum” or buzzing common in AC coils.

- Low Power Consumption: Significant energy savings in large-scale control systems.

- High Stability: Greater resistance to voltage fluctuations and electromagnetic interference.

Our DC Magnetic Contactor series is designed for seamless integration into modern control architectures. To ensure compatibility with various global standards, KRIPAL offers a wide array of coil voltage options, including 24VDC, 110VDC, and 220VDC. This flexibility allows engineers to precisely match the control system’s power supply, reducing the need for additional voltage converters.

Making the Right Choice

Deciding between AC and DC power is just the first step in optimizing your control system. The nuances of coil selection—ranging from power consumption to switching speed—can significantly impact your system’s long-term reliability.

For a technical deep dive into these specifications, explore our comprehensive AC Coil vs. DC Coil Contactors Selection Guide to ensure you choose the perfect match for your application requirements.

3. Air Conditioning Contactors

Space is often at a premium inside an air conditioner’s electrical cabinet. KRIPAL’s Air Conditioning Contactor series addresses this with a lightweight, compact footprint that makes installation fast and efficient. Specifically tailored for the rigorous demands of HVAC systems, these contactors are engineered to handle the unique starting characteristics of compressors and large fans. Unlike general-purpose units, Air Conditioning contactors are optimized for high inrush currents and are built for the high-frequency “on-off” cycling common in climate control.

- Best For: Residential central air units, commercial chillers, heat pump systems, and external condenser units.

- Key Engineering Advantages:

- Superior Thermal Management: Enhanced heat dissipation to handle continuous operation in outdoor environments.

- High Surge Tolerance: Specifically designed to withstand repeated inductive load spikes without contact welding.

- System Compatibility: Seamlessly integrates with standard HVAC control boards and thermostats.

We offer both 2-Pole (2P) and 3-Pole (3P) configurations to suit various system architectures.

4. Reversing Contactors

Building a reversing circuit from scratch can be time-consuming and prone to wiring errors. KRIPAL’s Reversing Contactor series offers a factory-assembled, pre-tested solution that is ready for immediate installation. Often referred to as Changeover Contactors, these units are an essential assembly of two AC contactors working in tandem. By alternating the closure of the two contact sets, they facilitate the precise control of forward and reverse motor rotation.

The defining feature of a reversing contactor is its integrated interlocking mechanism. This safety-critical design ensures that both contactors can never close at the same time, which would otherwise cause a catastrophic phase-to-phase short circuit.

- Best For: Bidirectional machinery such as conveyor belts, overhead cranes, hoists, elevator door operators, industrial mixers, and machine tool spindles.

- Key Engineering Advantages:

- Integrated Safety: Built-in interlocks provide a foolproof hardware-level defense against short circuits.

- Reliable Switching: Engineered for smooth transitions between directions, reducing mechanical stress on the motor.

- Design Simplicity: Consolidates multiple components into a single unit, significantly reducing the complexity of the control panel wiring.

By choosing a KRIPAL integrated unit, you eliminate the need for extra external wiring and separate interlock components. This not only speeds up your assembly process but also ensures that the interlocking timing is perfectly calibrated, providing a more reliable and compact solution for any application requiring motion reversal.

5. Mini Contactors

In modern electrical design, panel real estate is often at a premium. Mini Contactors are the specialized solution for this challenge. Engineered with an ultra-compact footprint, these devices are designed to handle low-current loads, typically ranging from 6A to 16A, without sacrificing the rugged switching performance of their full-sized counterparts.

- Best For: Small-scale ventilation fans, commercial lighting circuits, instrumentation control, and auxiliary low-power motor circuits.

- Key Engineering Advantages:

- Space Optimization: Their miniaturized structure allows for high-density mounting, enabling more control loops within smaller enclosures.

- Low Power Consumption: Optimized coils reduce energy draw and minimize heat dissipation, which is critical in tightly packed control cabinets.

- Ease of Integration: Designed for rapid installation on standard DIN rails or direct integration into compact machinery.

KRIPAL’s Mini Contactor series is built for high-performance reliability in restricted environments. While small in size, these units are constructed with high-grade materials to ensure a long electrical lifespan and consistent operation.

For engineers and OEMs looking to downsize their control cabinets without compromising on safety or functionality, KRIPAL provides a cost-effective solution that meets global standards.

6. Capacitor Switching Contactor

Specifically engineered for Reactive Power Compensation circuits, these contactors are the critical interface for switching power capacitors on and off the grid. The primary challenge in these applications is the massive “inrush current” (surge) that occurs the moment a capacitor is energized. Without specialized switching, this surge can weld contacts together and drastically shorten the lifespan of the capacitor.

KRIPAL’s capacitor contactors are designed to suppress these transients and minimize arcing, ensuring the stability of your Power Factor Correction (PFC) systems.

- Best For: Industrial power factor correction loops, reactive power compensation units in substations, and energy-saving systems for large-scale inductive loads.

- Key Engineering Advantages:

- Inrush Current Suppression: Equipped with specialized pre-contact blocks and damping resistors to limit peak current during startup.

- Arc-Quenching Excellence: Enhanced arc-suppression capabilities protect internal components from the high thermal stress of capacitor switching.

- Energy Efficiency: By improving the network’s power factor, these units help reduce energy losses and lower utility penalties for reactive power consumption.

Capacitors are expensive and sensitive components. KRIPAL’s Capacitor Switching Contactor series acts as a dedicated safeguard for your PFC bank. For facilities looking to optimize their power quality while minimizing maintenance costs, KRIPAL offers a factory-calibrated solution that meets the highest international safety and performance standards.

How to Select the Right Contactor

Selecting the correct contactor is about more than just matching a part number. It is about ensuring system longevity and safety. To guarantee your KRIPAL contactor performs optimally, follow these industry-standard selection criteria.

Step 1: Voltage Matching

For standard three-phase asynchronous motors, the rated current (I) can be quickly estimated using the following formula:

I≈2×P

Where:

- P= rated motor power (kW)

- I= current (A)

Example:

For a 10 kWÂ motor, the estimated current is approximately 20 A.

Tip:Â When selecting your contactor, always include a safety margin to handle startup current spikes and reduce contact wear.

Step 2: Understanding Utilization Categories

The type of load you are switching has a direct impact on contactor lifespan. According to IEC standards, loads are classified as follows:

Resistive Loads (AC-1)

Examples: Electric heaters, resistors, non-inductive or slightly inductive loads.

Selection Rule

Choose a contactor rated at 1.1 – 1.2 × the load current.

Inductive Loads (AC-3)

Examples: Squirrel-cage motors used in HVAC systems, pumps, compressors, and conveyors.

Selection Rule

Choose a contactor rated at 1.5 – 2 × the motor’s rated current to accommodate high inrush currents during startup.

Step 3: Voltage Coordination

Before installation, verify both voltage ratings:

- Main Circuit Voltage: Power supply voltage for the load (e.g., 380 VAC, 400 VAC, 480 VAC)

- Control Circuit (Coil) Voltage: Voltage used to energize the contactor (e.g., 24 VDC, 110 VAC, 220 VAC). Mismatched coil voltage is one of the most common causes of contactor failure during commissioning.

Step 4:Â Environmental & Operational Factors

The “Rated Current” on a spec sheet assumes standard operating conditions. You should “de-rate” the contactor (choose a higher capacity model) if your application involves:

- High-Frequency Switching: Extremely frequent start/stop cycles per hour.

- Extreme Ambient Temperatures: Operation in environments exceeding 40°C.

- High Altitudes: Installations above 2,000 meters, where thinner air reduces cooling efficiency and dielectric strength.

Conclusion

Whether you are managing a simple lighting circuit or a complex industrial motor array, the right contactor is the foundation of a reliable control system. By understanding the nuances between AC, DC, and specialized types like capacitor or reversing contactors, you can optimize your performance and minimize downtime.

For more detailed specifications, selection solutions, or customized quotes for specific contactors, please feel free to contact KRIPAL experts. We are committed to providing high-quality, globally certified switching solutions that balance technical excellence with cost-efficiency.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.