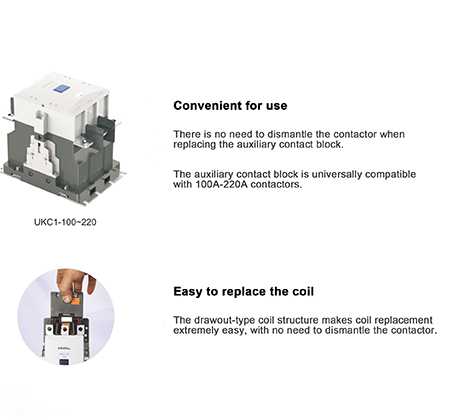

KRIPAL contactors (rated current: 100A to 800A) feature a drawout-type coil design. Coil replacement is extremely convenient, as there’s no need to dismantle the entire contactor during the process. KRIPAL independently manufactures 95% of its components, ensuring full quality control over the original factory coils.

Fault 2: Contact Welding & Pitting

Contact welding or pitting is a common failure mode in AC contactors and its symptoms are relatively easy to spot. When the contactor is supposed to disconnect the power, but the motor continues running, it’s a clear indication that the contacts have become welded together. Another visible symptom of contact welding is the appearance of discolored or blackened contact surfaces, a result of the excessive heat generated when the contacts fail to open properly. The blackened surfaces are often the result of arcing caused by high current flowing through the contactor contacts, which have become fused together.

Core Causes for Contact Welding & Pitting

- Overload Current: If the electrical load exceeds the rated current capacity of the contactor, the contacts can overheat, leading to welding. This can happen when the connected motor draws more current than the contactor is designed to handle.

- Incorrect Contact Rating: Using a contactor with an inappropriate current rating for the connected load is another common cause. For example, using an AC-1 contactor (designed for resistive loads) to control an AC-3 motor load (which requires a contactor rated for motor control) can result in premature failure of the contacts.

Troubleshooting and Solutions

KRIPAL contactors come standard with high-quality silver contacts. This core component not only ensures tight contact alignment between the contacts—greatly boosting electrical conduction sensitivity and contact stability—but also, leveraging silver’s exceptional electrical properties, reliably handles large instantaneous currents. It delivers robust hardware support for the stable operation of various electrical circuits.

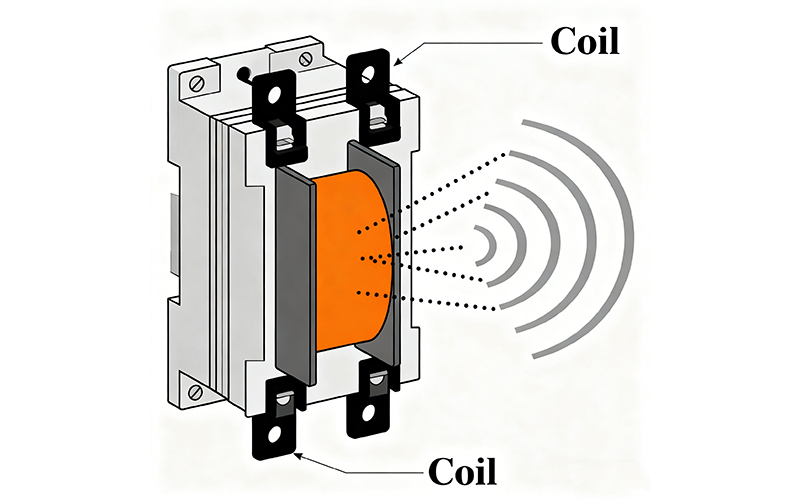

Fault 3: Excessive Humming or Chattering Noise

A common issue with AC contactors is excessive humming or chattering when the contactor is activated. This noise is typically produced when the magnetic moving core (also called armature in industry terms) or stationary core moves in an irregular manner. It can be quite noticeable, especially in quiet environments. The humming sound is often continuous, even after the contactor has fully engaged. If the contactor is producing a chattering sound, this indicates that the moving core or stationary core is not seating properly, causing it to vibrate as it attempts to complete the circuit. The presence of this noise indicates a mechanical malfunction or interference.

Core Causes for Humming or Chattering Noise

- Debris on Armature or Stationary core: Foreign materials such as dust, oil, or metal shavings can become trapped between the armature and stationary core, disrupting the smooth movement required for proper operation. This can lead to irregular magnetic attraction and the resulting noise.

- Broken Shading Ring: The shading ring helps maintain the magnetic field necessary for proper contactor operation. If this component is broken or deteriorated, the contactor may not function smoothly, which can cause buzzing or chattering sounds.

Maintenance Actions

- Clean the Armature and Stationary core: Disconnect the power supply and clean the armature and stationary coreusing a soft cloth. Ensure there is no oil, dust, or debris present that could obstruct movement.

- Inspect the Shading Ring: Check the shading ring for any signs of wear or damage. If it is broken or cracked, replacing it can eliminate the source of the noise.

Fault 4: Slow or Incomplete Engagement

When the contactor engages too slowly or fails to engage fully, the system will experience delays in operation. This can lead to motors starting up at lower speeds or inefficiently. In some cases, the contacts might fail to close entirely, resulting in partial or no power delivery to the motor or device. Slow engagement can significantly affect the performance of equipment that relies on the contactor for operation, such as HVAC systems or industrial machinery.

Core Causes for Slow or Incomplete Engagement

- Excessive Spring Tension: The spring that resets the contacts after each cycle might be too tight, leading to sluggish operation. The spring tension must be carefully calibrated to ensure proper contact engagement.

- Corrosion or Physical Obstructions: If the contactor is exposed to a dirty or corrosive environment, physical obstructions such as rust, dust, or debris can block the movement of the mechanical components, slowing down engagement.

Recommendations

- Check Spring Tension: Ensure the reset spring is not over-tensioned. If necessary, adjust the spring tension according to the manufacturer’s specifications.

- Inspect for Corrosion: Clean and remove any corrosion or physical obstructions that might be impeding the movement of the contactor. In particularly harsh environments, consider upgrading to a contactor with dust covers to protect against debris buildup.

Fault 5: Electrical Arcing During Contact Opening

Electrical arcing typically occurs when the contactor attempts to open and break the electrical circuit. This arcing can produce visible sparks and cause damage to the contacts over time. The symptoms include blackened or pitted contact surfaces, as well as a burning smell. Arcing can also cause the contactor to fail to properly disengage the circuit, leading to continuous power flow, even after the control signal has been removed. This issue is particularly common in circuits that deal with high inrush currents or inductive loads.

Core Causes for Electrical Arcing During Contact Opening

- Inductive Loads: Devices such as motors, solenoids, or transformers are inductive, meaning they generate a high inrush current when powered on. When the contactor opens to disconnect the circuit, the collapsing magnetic field can cause arcing.

- Insufficient Contact Pressure: If the contact pressure between the contacts is too low, it can result in poor separation of the contacts, leading to increased arcing.

Troubleshooting and Solutions

- Use Snubbers or Arc Suppressors: Installing snubber circuits or arc suppressors across the contacts can help dissipate the energy generated by inductive loads, reducing the likelihood of arcing.

- Increase Contact Pressure: Ensure that the contacts are engaging with the appropriate pressure. If the pressure is too low, it can lead to arcing during contact separation.

- Upgrade to a Higher-Rated Contactor: For circuits with high inrush currents, use a contactor specifically designed to handle such loads. Contactors designed for inductive loads are built to withstand the high voltage spikes caused during disconnection.

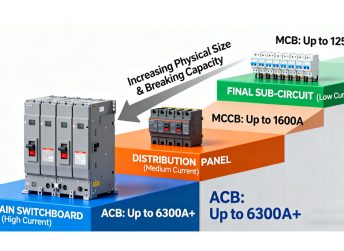

Expert Selection Tips

To prevent frequent failures and ensure reliable operation, selecting the right AC contactor is critical. KRIPAL Electrical, a leading manufacturer, offers products with high-quality contact materials and durable components. Here are some tips for selecting a contactor that will last longer:

- Choose Silver Alloy Contacts: Silver alloy contacts are resistant to arcing, which helps reduce wear and tear over time.

- Opt for High-Temperature Coils: Coils rated for higher temperatures tend to last longer, especially in environments where heat is a concern.

- Select Appropriate Load Rating: Always choose a contactor with the correct load rating to match the connected motor or device. Overloading can cause premature failure.

For more information on KRIPAL’s range of contactors, browse our contactors catalogue or contact our expert for professional advice.

FAQ

How often should I inspect my contactors?

It is recommended to inspect your contactors at least once every six months. Regular inspections should include checking for proper operation, cleaning contacts, and tightening any loose connections. For high-usage systems, more frequent checks may be necessary.

Why is my contactor making a buzzing noise when it is engaged?

A buzzing or humming sound typically indicates that the armature or plunger inside the contactor is not moving smoothly. This could be caused by debris or dirt on the components, or it could indicate a malfunctioning shading ring. Cleaning the contactor and inspecting the shading ring can resolve the issue.

Can moisture or dust affect the performance of an AC contactor?

Yes, moisture and dust can significantly impact the performance of an AC contactor. Moisture can cause short circuits, while dust and debris can obstruct the movement of mechanical parts. In environments with high dust or moisture, it is advisable to use contactors with protective covers or seals to prevent damage.

What is the proper way to clean the contactor's contacts?

Cleaning the contacts should be done carefully to avoid damaging the surface. Use a fine abrasive pad or contact cleaner to remove any pitting, discoloration, or corrosion. Never use harsh chemicals or coarse materials that could further damage the contact surface. If the contacts are too worn, replacement is necessary.

How can I prevent contactor failure from overload conditions?

To prevent overload conditions, ensure that the contactor is correctly sized for the motor or device it controls. Also, installing overload protection devices like circuit breakers or fuses can help protect the contactor from excessive current and prevent premature failure.

Troubleshooting Table

| Fault |

Symptoms |

Causes |

Solution |

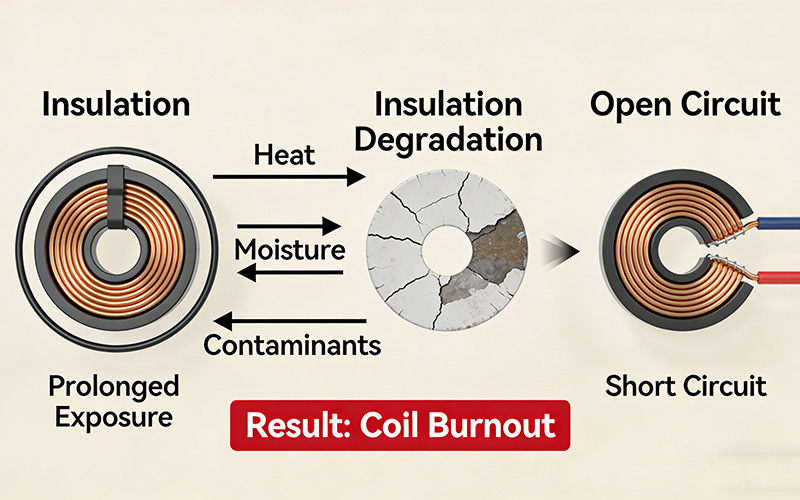

| Coil Burnout |

Contact not engaging, burnt smell |

Voltage fluctuations, insulation degradation |

Measure voltage, inspect fuse, replace contactor |

| Contact Welding/Pitting |

Motor running after control signal off |

Overload current, incorrect contactor rating |

Check load current, clean or replace contacts |

| Excessive Humming/Chattering |

Persistent humming sound |

Debris on armature, broken shading ring |

Clean armature, replace shading ring |

| Slow/Inadequate Engagement |

Slow or incomplete engagement |

Excessive spring tension, corrosion |

Adjust spring tension, clean contactor parts |

| Electrical Arcing |

Blackened contacts, burning smell |

Inductive loads, insufficient contact pressure |

Use snubbers, increase contact pressure, upgrade contactor |

By recognizing the common causes of AC contactor failure and knowing how to troubleshoot them, you can keep your electrical systems running efficiently and avoid unnecessary downtime. Remember, selecting a high-quality contactor like those from KRIPAL can significantly enhance the reliability and longevity of your equipment.