Zhejiang KRIPAL Electric Co., Ltd. has been officially recognized as a 2025 Zhejiang Provincial Green and Low-Carbon Factory, setting a strong example for green and sustainable development within the electrical manufacturing industry.

- Enhancing Quality from the Inside Out

- Digital Transformation Strengthening Capabilities Through Cloud and Data Integration

- Green Manufacturing Leading Sustainable Development

- Automated Production Lines Improving Quality and Reducing Energy Consumption

- Solar Power Systems Supporting a Greener Energy Future

- CNAS Laboratory Driving Innovation for Green Development

- Looking Ahead Continuing to Advance the Green Transformation

Enhancing Quality from the Inside Out

KRIPAL Electric adheres to the philosophy of “aligning all operations with production, guiding production through quality, and driving quality through market needs.” The company continues to strengthen coordination across processes and equipment while optimizing every stage of manufacturing, including personnel, machines, materials, methods, environment and measurement.

By focusing on lean management and innovation-driven improvement, KRIPAL has reengineered systems and workflows to create a highly efficient, standardized and collaborative management model. The factory maintains industry-leading labor productivity and has been recognized as a “National Specialized and Innovative Little Giant Enterprise” and a “Zhejiang Specialized and Innovative SME.”

Digital Transformation Strengthening Capabilities Through Cloud and Data Integration

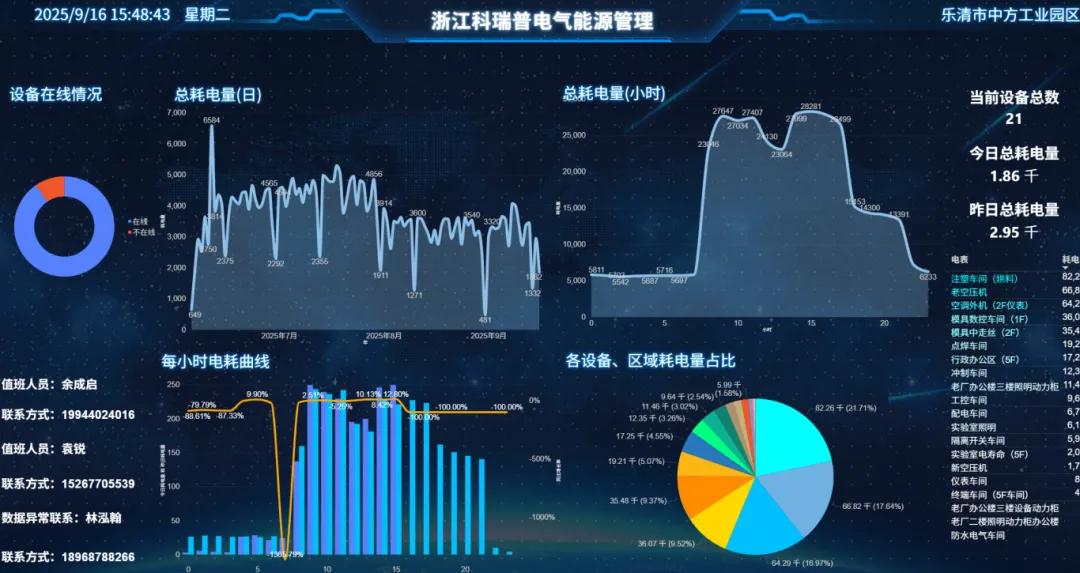

Guided by the industry’s digital transformation strategy, KRIPAL Electric has adopted a three-step approach of “cloud adoption, data utilisation and intelligent empowerment.” Through a dual architecture of traditional systems combined with cloud platforms, the company has developed five major smart application scenarios.

This digital transformation enables seamless integration of data and operations, real-time monitoring of key indicators and collaborative management of core risks. These capabilities provide strong digital foundations for green and sustainable manufacturing.

Green Manufacturing Leading Sustainable Development

KRIPAL Electric remains committed to green and low-carbon operations, integrating environmental protection principles throughout its production and management processes. The company has earned certifications under ISO 14001 Environmental Management, ISO 45001 Occupational Health and Safety, and ISO 9001 Quality Management, establishing a complete green factory management framework.

In areas such as resource utilization, energy efficiency and clean production, KRIPAL performs significantly above industry averages. The factory achieves land efficiency, harmless raw material use, clean production, waste recycling and low-carbon energy utilization.

Automated Production Lines Improving Quality and Reducing Energy Consumption

Through the introduction of automated production lines and digitalized equipment, KRIPAL has achieved more refined production management and enhanced operational efficiency. Automated systems replace traditional manual processes, improving product consistency while lowering overall energy consumption.

Using PLC control systems and digital monitoring platforms, the company can track energy usage in real time and optimize energy allocation, reducing unnecessary consumption. These upgrades significantly increase manufacturing efficiency and reduce defect rates, supporting KRIPAL’s long-term green development goals.

Solar Power Systems Supporting a Greener Energy Future

The photovoltaic array installed on the factory rooftop creates a powerful “energy field.” Working together with the company’s energy storage system, it enables peak-valley energy balancing. Approximately 20 percent of the company’s electricity now comes from solar energy, reducing annual carbon emissions equivalent to planting tens of thousands of trees.

KRIPAL not only adopts solar energy internally but also provides intelligent power distribution equipment and components for the solar and renewable energy industries, playing an important role in both photovoltaic and energy storage sectors.

CNAS Laboratory Driving Innovation for Green Development

KRIPAL has invested in building a high-standard CNAS-accredited laboratory, which provides critical technical support for green product design and manufacturing. The laboratory can calculate carbon emissions across a product’s full lifecycle, offering reliable data for carbon footprint assessments and carbon labeling initiatives.

By researching green materials and processes, the laboratory emphasizes recyclability, promotes standardized designs and enhances product longevity. These innovations provide continuous momentum for the company’s green transformation.

Looking Ahead Continuing to Advance the Green Transformation

Receiving the Green and Low-Carbon Factory designation is both an honor and a responsibility. KRIPAL Electric will continue to uphold its green development principles, strengthen green manufacturing capabilities and explore new models such as green energy applications and virtual factory operations.

The company plans to further advance energy-saving technological upgrades and accelerate the development of a low-carbon smart factory. Through improvements in energy consumption, product design and energy utilization, KRIPAL will continue to drive green and low-carbon transformation and contribute to the sustainable and intelligent development of the manufacturing sector.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.