Yunnan Sanjiang Industrial Power Project

October 09, 2025

The Yunnan Sanjiang Project is one of KRIPAL’s standout installations in Southwest China, showing how advanced industrial power systems can perform safely and reliably even in remote and challenging environments. Located in a mountainous area of Yunnan Province, this project required a robust and flexible electrical connection solution that could support heavy machinery and ensure uninterrupted power for daily operations.

The site operates under complex environmental conditions, including high humidity, temperature variation, and exposure to dust and outdoor elements. The client’s main goal was to create a safe, stable, and easy-to-maintain electrical infrastructure that could withstand long-term use while meeting strict industrial safety standards.

KRIPAL’s engineering team designed and supplied a customized power distribution system using industrial-grade sockets, waterproof enclosures, and high-performance circuit protection devices to meet those needs.

Project Overview

The Yunnan Sanjiang facility is located in a high-altitude region where weather and terrain create significant challenges for traditional power installations. The site includes several outdoor operation zones, maintenance platforms, and processing units that all rely on stable electricity to run various types of equipment.

Instead of using a centralized electrical room, the client requested a distributed power system—a solution that allows safe and efficient power access at multiple points around the facility. Each area required separate connection boxes equipped with industrial sockets that could handle high current loads while remaining easy to access for technicians.

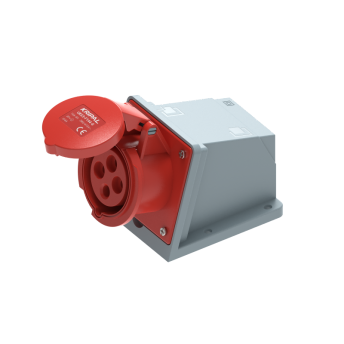

KRIPAL engineers proposed a modular design using metal-clad power distribution boxes fitted with IP67 waterproof and dustproof sockets, ensuring complete protection against rain and dust ingress.

KRIPAL’s Engineering Solution

The power panels and sockets used in this project were selected from KRIPAL’s proven range of industrial connectors and distribution units. Each unit was customized to match the site’s operational voltage and load requirements.

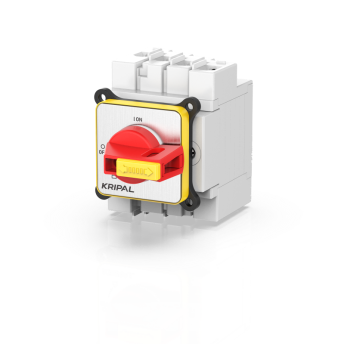

The enclosures were built using corrosion-resistant steel and coated with an anti-rust finish suitable for outdoor and semi-industrial environments. All sockets were fitted with mechanical interlocks that prevent accidental disconnection during use, while circuit breakers and overload protection components provided additional safety.

KRIPAL’s IP67-certified sockets and plugs were key to the design. These connectors ensure complete sealing against moisture and dust, even in harsh weather. The high mechanical strength of the casings also means they can withstand impacts or vibration from nearby machinery without compromising performance.

Every detail, from the cable entry systems to the panel mounting and labeling, was carefully planned to simplify future maintenance and guarantee long-term reliability.

Installation and Operation

Installation was carried out under KRIPAL’s supervision, with on-site support from its technical service team. Because of the uneven terrain and outdoor exposure, the installation design had to ensure both safety and accessibility. The boxes were mounted at strategic points along operational platforms and structural pillars to minimize cable runs and make inspection convenient.

Once powered on, the KRIPAL system delivered consistent electrical performance with minimal energy loss. The distribution boxes provided stable power to all connected equipment, and technicians reported that the system was easy to manage thanks to the clear labeling and ergonomic layout of the sockets.

The compact design of the power modules also saved valuable space while keeping the installation clean and organized, enhancing the overall safety of the site.

Results and Client Feedback

Since completion, the Yunnan Sanjiang facility has reported excellent stability in its power network. The KRIPAL electrical systems have proven to be resistant to both weather changes and heavy-duty usage.

Maintenance staff particularly appreciated how easy it was to perform routine inspections—connections were simple to check, and the high-grade materials used in the sockets significantly reduced wear and corrosion over time.

The project not only improved operational reliability but also enhanced safety standards across the facility. Operators noted a noticeable reduction in electrical faults and downtime after KRIPAL’s system was put into use.

The client praised KRIPAL for its professionalism, flexibility, and product quality, emphasizing that the solution exceeded expectations in both performance and durability.

Conclusion

The Yunnan Sanjiang Project perfectly represents KRIPAL’s capability to provide tailor-made electrical solutions for demanding environments. From system design to on-site execution, every stage reflected KRIPAL’s focus on safety, efficiency, and long-term value.

By combining innovation with practical engineering, KRIPAL helped the client establish a power distribution system that is not only reliable but also future-proof.

Projects like this show why KRIPAL is trusted by industrial partners across China and beyond—delivering dependable, high-performance electrical solutions wherever stable and safe power is needed.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

-344x344.png)