ABB Factory Charging & Power Safety Optimization

October 27, 2025

Project Overview

At ABB’s industrial facility, the team set out to make every charging station safer, smarter, and more efficient. The goal was simple: create a clean, well-organized, and energy-efficient environment where forklifts, cleaning machines, and other electric vehicles could be charged without risk.

This project combined engineering precision with EHS (Environment, Health & Safety) best practices to reduce electrical hazards, standardize layouts, and optimize power consumption across the plant.

The Challenge

Before the upgrade, the charging areas looked functional but not ideal.

Cables often lay on the floor, ventilation was limited, and different charging machines were placed too close together. Some stations lacked clear boundaries or visible warning signs, while others showed marks from acid leaks or electrical overloads. These small issues added up — increasing safety risks and wasting valuable time during operations.

Our Approach

ABB’s improvement plan focused on both safety and efficiency. The charging zones were completely reorganized to separate forklifts and cleaning equipment. Each station was given enough space for maneuvering, with bright yellow lines marking clear parking and cable areas.

New acid-resistant platforms were installed, along with cable hooks that kept wires off the ground. The ventilation system was strengthened to remove battery gases quickly, and additional fire extinguishers were placed nearby.

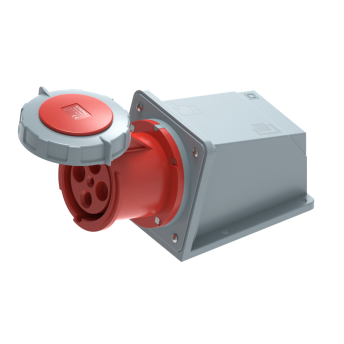

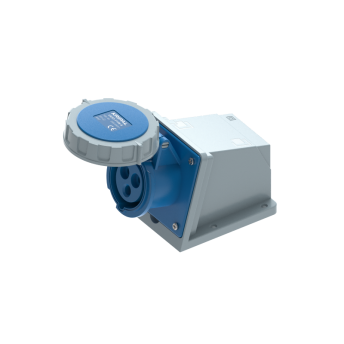

The electrical network was also upgraded. Every charging point received its own protected circuit with residual-current devices (RCDs) for instant fault detection. Industrial sockets with IP55 protection ensured safety even in humid environments. To make monitoring easier, digital energy meters were connected to a central dashboard, allowing the team to see real-time power usage and identify problems before they caused downtime.

Training and Safety Culture

Technology alone wasn’t enough — people mattered just as much.

New bilingual safety procedures were introduced and displayed at every charging area. Employees attended short, hands-on training sessions covering daily checks, emergency response, and correct cable handling. Over time, this created a strong culture of awareness and responsibility.

The Results

The difference was visible almost immediately.

The plant reported zero electrical or chemical incidents after the upgrade. Charging became faster and more organized, cutting waiting time by 30%. Smart energy scheduling reduced electricity costs by about 15%. More importantly, the entire site reached full compliance with ABB’s EHS standards and ISO 45001 safety requirements.

The project proved that a thoughtful approach to electrical design and workplace organization can deliver both safety and performance.

Lasting Impact

Today, ABB’s charging zones stand as a model for safe industrial power management.

The system is reliable, visually clean, and ready to expand as new equipment arrives. By combining digital monitoring with clear procedures, ABB has created a sustainable and scalable solution for its global operations — one that balances human safety, operational efficiency, and environmental responsibility.

How can we assist you?

Tell us a bit more so we can route your request to the right expert.

-344x344.png)