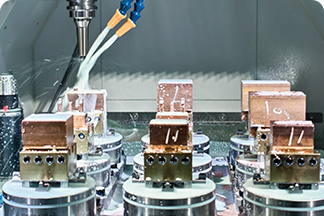

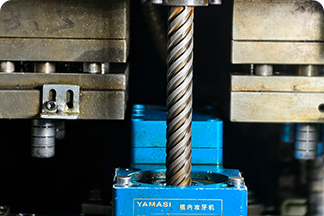

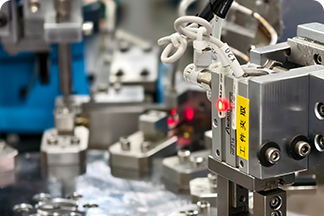

With over 30 years of industry experience, we are a recognized leader in the low-voltage electrical sector and a key enterprise in Wenzhou. Our manufacturing strength is anchored in three major production bases totaling 100,000 m², featuring 32 production lines capable of producing more than 200 product types annually.

We achieve complete vertical integration through 100% in-house component manufacturing using automated production and assembly, supported by a dedicated R&D team and a state-of-the-art laboratory. Our commitment to responsible manufacturing is demonstrated by our SMETA certification, obtained in 2025.