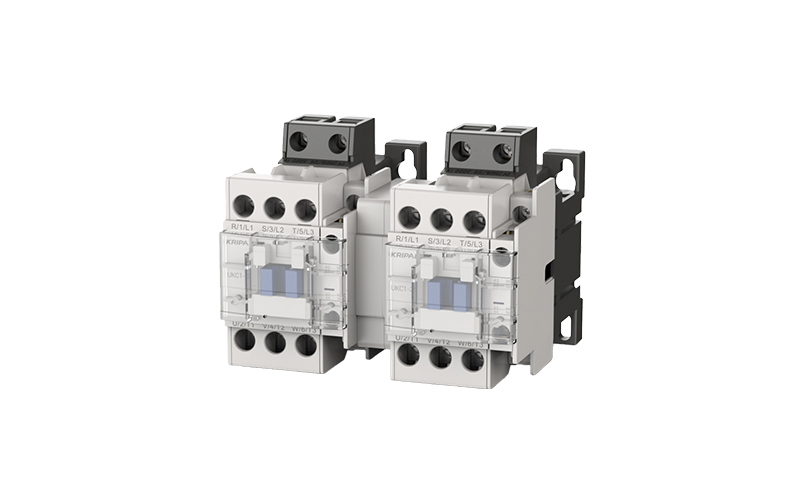

Reversing Contactor

Control and Protection - Reversing Contactor

KRIPAL Reversing Contactor is specifically engineered for forward/reverse operation of loads, primarily AC motors. Its core principle involves alternating the power-on and power-off states of two sets of main contacts to change the power phase sequence to the motor stator windings, thereby reversing the motor’s rotation direction.

Get A Quote

Control and Protection - Reversing Contactor

KRIPAL Reversing Contactor is specifically engineered for forward/reverse operation of loads, primarily AC motors. Its core principle involves alternating the power-on and power-off states of two sets of main contacts to change the power phase sequence to the motor stator windings, thereby reversing the motor’s rotation direction. It integrates forward control, reverse control, and mechanical interlocking protection into a single unit, making it ideal for motor drive applications requiring bidirectional operation and combining efficient control with enhanced safety. The unified design eliminates the need for assembling two separate contactors and additional interlock components, reducing wiring effort and saving significant panel space. For cost-effective maintenance, the contact tips are replaceable individually (certain models support modular contact cartridge replacement), avoiding the need for a full contactor replacement.

Core Safety & Performance Features

Dual Interlocking Protection: Integrates both mechanical and electrical interlocks to completely prevent the simultaneous closure of the two main contactors, thereby eliminating the risk of phase-to-phase short circuits. This is the fundamental safety advantage of the reversing contactor.

Overload & Short-Circuit Compatibility: Can be used in conjunction with thermal overload relays and circuit breakers to provide a complete motor control solution combining “forward/reverse control + overload protection + short-circuit protection”.

Excellent Arc Extinguishing Performance: The main contacts, often made of silver alloy, work in conjunction with a fully enclosed arc chute to suppress electric arcing during contact operation. This reduces contact erosion and significantly extends service life.

Typical Applications

Machine Tools: Controls the forward/reverse rotation of spindles in lathes and milling machines, enabling forward cutting and reverse retraction of workpieces.

Hoisting Equipment: Manages the up/down movement of electric hoists and lifts by reversing motor direction, often coordinated with limit switches for safe starting and stopping.

Conveying Systems: Provides forward (feeding) and reverse (returning) operation for belt conveyors, accommodating bidirectional material handling needs in production lines.

Frequently Asked Questions

Explore FAQ >How can we assist you?

Tell us a bit more so we can route your request to the right expert.